Copper Alloy Welding Materials

Alright, this is a comprehensive and systematic explanation of the classification and use of copper alloy welding materials.Copper Alloy Welding Materials.

Welding copper alloys is quite challenging due to their high thermal conductivity, susceptibility to oxidation, evaporation of certain elements, and tendency to form hot cracks. Selecting the right welding material is key to ensuring welding quality.

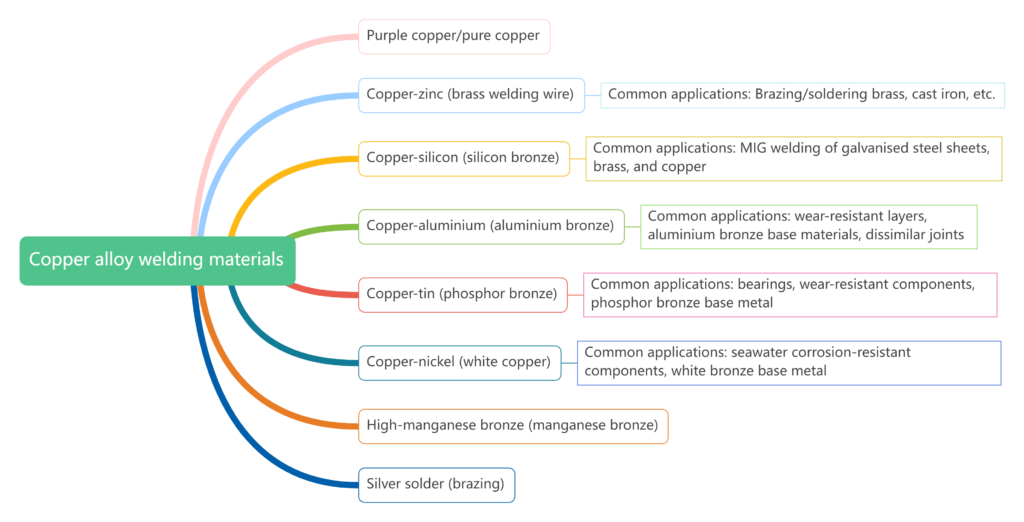

Overview of Copper Alloy Welding Material Classification

Copper alloy welding materials are typically classified based on their primary alloying elements to match or complement the properties of the base material being welded (such as colour, strength, corrosion resistance, and electrical conductivity). The following diagram clearly illustrates the main classifications and their relationships:

Below, we’ll delve deeper into the characteristics, grades, and typical uses of each category.

Detailed Explanation and Applications of Various Welding Materials

1. Red Copper/Pure Copper

This type of welding wire is primarily used for welding pure copper (red copper).

· Grade Example:

· ERCu (AWS A5.7 Standard): For example, ERCu, with a copper content of ≥98%.

· HSCu (National Standard): For example, HSCu.

· Features:

· High electrical and thermal conductivity, matching the base material.

· Poor weldability: Because red copper conducts heat very quickly, a high-power heat source and high preheating temperature (300-600°C) are required.

· Low tensile strength: Approximately 80%-90% of that of the base material.

· Main Application: Welding of pure copper components requiring high electrical conductivity, such as electrical busbars, transformer windings, and heat exchangers.

2. Copper-Zinc (Brass Welding Wire)

· Example Grades:

· RBCuZn-X (AWS A5.7/ASME SFA-5.7): Common examples include RBCuZn-1 (Cu60ZnSn) and RBCuZn-2 (Cu60ZnSnFe).

· HSCuZn-X (National Standard): Examples include HSCuZn-1 and HSCuZn-2.

· Features:

· Typically used for brazing or gas welding, rather than MIG/TIG welding (because zinc vaporization produces toxic fumes and causes porosity).

· Excellent fluidity and a relatively low melting point.

· Excellent for joining dissimilar materials such as copper, steel, and cast iron during brazing.

· Main Applications: Brazing carbon steel, cast iron, and carbide; repairing cast iron parts; and craft production.

3. Copper-Silicon (Silicon Bronze)

The CuSi3 you asked about earlier belongs to this category and is a widely used copper alloy welding consumable.

· Example grades:

· ERCuSi-A (AWS A5.7): CuSi3, composition Cu-(2.8-4.0)Si-(≤1.5)Mn.

· HSCuSi (National Standard).

· Features:

· Excellent weldability: The addition of silicon significantly reduces the surface tension of the molten metal, resulting in good fluidity, minimal spatter, a stable arc, and aesthetically pleasing weld bead formation.

· Excellent mechanical properties: Excellent strength and toughness.

· Good corrosion resistance: Particularly resistant to atmospheric and seawater corrosion.

· Color matching: The weld color closely matches that of the parent metal in many copper alloys (such as brass).

· Main applications:

· MIG welding: Particularly suitable for welding galvanized steel (silicate slag systems can reduce zinc burnout). Welding of copper-silicon alloys and copper-zinc alloys (brass).

Used for overlay welding of steel to provide a corrosion-resistant layer.

4. Copper-Aluminum (Aluminum Bronze)

Example grades:

ERCuAl-A2, ERCuAl-A3 (AWS A5.7): For example, ERCuAl-A2 (Cu-7Al-2Fe), ERCuAl-A3 (Cu-9Al-1Fe).

HSCuAl (National Standard): For example, HSCuAl-1, HSCuAl-2.

Features:

High strength, high hardness, and excellent wear resistance.

Excellent corrosion resistance, especially resistance to seawater erosion, dilute sulfuric acid, and alkaline solutions.

Fouling resistance: Resists the growth of marine organisms in marine environments.

Main applications:

Welding aluminum-bronze base metals (such as ship propellers). · Hardfacing of wear-resistant surfaces (such as bearings, gears, and valve sealing surfaces).

· Welding of dissimilar joints between copper alloys and steel.

· Repair of cast iron parts.

5. Copper-Tin (Phosphor Bronze)

· Example grades:

· ERCuSn-A (AWS A5.7): e.g., ERCuSn-A (Cu-6Sn-0.1P), ERCuSn-C (Cu-8Sn-0.1P).

· HSCuSn (National Standard).

· Features:

· Good strength, toughness, and wear resistance.

· High fatigue strength.

· Good corrosion resistance.

· Main Applications:

· Welding of phosphor bronze base metals (such as springs, bearings, and bellows).

· Welding of dissimilar joints between copper alloys and steel.

6. Copper-Nickel (White Cup)

· Example grades:

· ERCuNi (AWS A5.7): e.g., ERCuNi (Cu-10Ni-1.4Fe-0.5Mn), ERCuNi30 (Cu-30Ni-0.6Fe-1.5Mn).

· HSCuNi (National Standard).

· Features:

· Excellent resistance to seawater corrosion and marine biofouling.

· Resistant to various acids and alkalis.

· High strength, with a thermal expansion coefficient close to that of carbon steel.

· Main Applications:

· Welding of white cup base metal (e.g., ship seawater piping, condensers, and desalination units).

· Welding of dissimilar joints between copper-nickel alloys and steel.

7. Nickel-Aluminum Bronze

This is a high-performance branch of aluminum bronze.

· Grade Example: ERCuNiAl (Cu-9Al-4.5Ni-4Fe-1Mn).

· Features: One of the best copper-based welding consumables with the best overall performance, offering exceptional strength, hardness, wear resistance, and exceptional resistance to seawater cavitation and impact corrosion.

· Main Application: Welding high-performance nickel-aluminum bronze base metals, such as highly stressed propellers and pump and valve components for naval vessels.

—

Key Principles for Selecting Welding Consumables

1. Matching Base Metal Properties: First, consider the core requirements for the weld. Is it conductivity, corrosion resistance, strength, color, or wear resistance? Select a welding consumable that provides the appropriate performance.

2. Matching Base Metal Composition: When welding the same materials, a welding consumable with the same or similar composition as the base metal is generally selected (e.g., ERCu for copper and ERCuAl-A2 for aluminum bronze).

3. Welding Dissimilar Materials: Consider the compatibility of the two metals (e.g., thermal expansion coefficient, potential difference), melting point, and welding process. Silicon bronze, aluminum bronze, and phosphor bronze are commonly used to join copper and steel.

4. Welding Process:

· TIG welding (GTAW): Typically uses straight wire, requiring high arc stability and weld bead shape, with silicon bronze offering excellent performance.

· MIG welding (GMAW): Uses coiled wire, offering high efficiency and suitable for long welds and automated welding.

· Brazing: Uses a brazing filler metal with a melting point much lower than that of the parent metal (such as brass or silver), relying on capillary action to fill the joint.

Precautions

· Intensive preheating: Preheating is required when welding pure copper and thick, large-section workpieces to reduce heat input differences and prevent incomplete fusion and porosity.

· Cleaning: Before welding, thoroughly remove oil, moisture, and oxide films (CuO easily forms on copper surfaces) from the workpiece and wire surfaces.

· Ventilation: When welding brass (zinc vaporization) or using brazing filler metals containing cadmium, ensure good ventilation and wear respiratory protection. Hot Cracking: Certain copper alloys (such as phosphorus-deoxidized copper) are prone to hot cracking. This can be suppressed by using welding wires containing deoxidizing elements such as phosphorus, silicon, and manganese.

We hope this detailed classification and usage guide will help you better understand and select copper alloy welding consumables.