Nickel Alloys Welding

Regarding nickel alloy welding materials, this is a highly important and specialised topic. Nickel alloys, renowned for their exceptional high-temperature resistance, corrosion resistance, and mechanical properties, are widely used in aerospace, energy, chemical, and marine engineering industries. However, their weldability presents unique challenges, making the proper selection of welding materials critical.Nickel Alloys Welding.

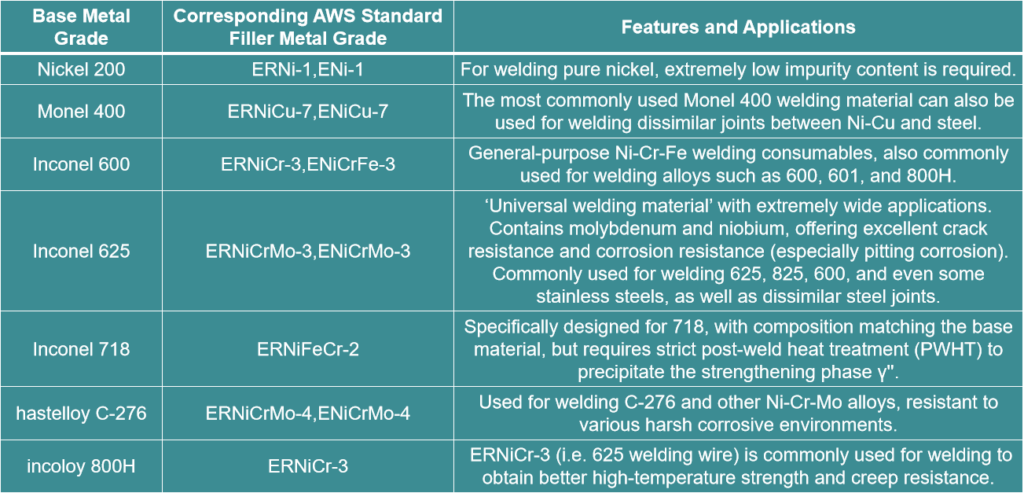

Below, I will provide a comprehensive overview of nickel alloys, including their classification, welding challenges, common welding material selections, and key welding process considerations.

I. Main Classification of Nickel Alloys

Before selecting welding materials, it is essential to identify the type of nickel alloy being welded. The main categories include:

1. Industrial pure nickel: e.g., Nickel 200 (UNS N02200). It has excellent corrosion resistance and electrical conductivity but lower strength.

2. Nickel-Copper Alloys (Monel Alloys): such as Monel 400 (N04400) and Monel K-500 (N05500). These alloys are renowned for their excellent resistance to seawater and acid-alkali corrosion.

3. Nickel-chromium alloys (Inconel alloys/heat-resistant alloys): such as Inconel 600 (N06600), Inconel 625 (N06625), Inconel 718 (N07718). These alloys exhibit excellent high-temperature strength and oxidation resistance.

4. Nickel-Chromium-Iron Alloys (Incoloy Alloys): Examples include Incoloy 800 (N08800) and Incoloy 825 (N08825). These alloys bridge the gap between nickel alloys and stainless steel, balancing corrosion resistance and cost-effectiveness.

5. Nickel-molybdenum alloys (Hastelloy alloys): such as Hastelloy B-2 (N10665) and Hastelloy C-276 (N10276). These alloys exhibit exceptional resistance to corrosion in reducing media.

II. Major Challenges in Welding Nickel Alloys

1. Sensitivity to Hot Cracks: Nickel alloys are highly sensitive to low-melting-point impurities such as S, P, Pb, and Bi, which form liquid films at grain boundaries, leading to solidification cracks (centre cracks in the weld) and liquefaction cracks (cracks in the heat-affected zone).

2. Porosity tendency: The liquid nickel alloy melt pool is viscous and has poor fluidity, making it difficult for dissolved gases (such as hydrogen and oxygen) to escape, leading to porosity formation.

3. Poor weld metal wettability: The viscous melt pool and high surface tension can result in poor weld bead formation (such as bulges or undercut) and incomplete fusion defects.

4. Precipitation phase sensitivity: Certain alloys (e.g., Inconel 718) are sensitive to precipitation phases during aging. Inappropriate heat input can lead to a decline in the properties of the heat-affected zone.

.

Important Note:

· Dissimilar Metal Welding: Typically, welding materials with higher alloy content and better plasticity than the base metals are selected. For example, when welding stainless steel and nickel alloys, ERNiCr-3 or ERNiCrMo-3 (625) are common choices.

· Flux-cored wire (FCAW): For welding large structural components made of nickel alloys, flux-cored wire (such as Ni 625 TFC) is more efficient and increasingly widely used.

· Submerged arc welding (SAW): Typically, a combination of welding strip and flux is used, with the flux better controlling the chemical composition and properties of the weld.

IV. Key Points of Welding Process

1. Thorough Cleaning: This is the most critical step! Specialised stainless steel wire brushes and solvents such as acetone must be used to thoroughly remove all contaminants from the groove and its sides, including oil, moisture, paint, and marker pen marks.

2. Limit heat input: Use a smaller welding current and faster welding speed. Avoid excessive heat input, which can cause grain coarsening and hot cracks. When performing multiple passes, control the interpass temperature (typically recommended below 150°C).

3. Joint design: Due to poor melt pool fluidity, the bevel angle should be larger than that for carbon steel (e.g., 70–80° for a V-groove), and the root gap should be appropriately increased to ensure full penetration and good fusion.

4. Arc characteristics: For TIG welding, use direct current positive polarity (DCEN). For MIG welding, pulse arc or short-circuit transition modes are more advantageous for controlling the melt pool.

5. Weld bead profile: Use small oscillation or straight-line welding, with oscillation width not exceeding three times the wire diameter. Fill the crater when extinguishing the arc to prevent crater cracks.

6. Back side protection: For single-sided welding with double-sided formation, high-purity argon gas (99.999%) must be used for back side protection to prevent root oxidation.

Summary

Selecting nickel alloy welding materials is a systematic process that requires:

1. Identifying the base material: Determine the specific grade of the base material to be welded.

2. Understanding the operating conditions: Understand the environmental conditions (temperature, corrosive media) and stress conditions of the joint.

3. Following standards: Refer to standards such as AWS to select the appropriate welding material grade and consult the technical documentation provided by the supplier.

4. Strictly adhere to welding procedures: Develop and strictly enforce welding procedure specifications (WPS) that include cleaning, preheating, interpass temperature control, welding parameters, and post-weld treatment (if required).

For critical components, it is recommended to conduct welding procedure qualification (PQR/WPQ) prior to formal welding to verify the suitability of the selected materials and processes. If there are any uncertainties, consult the material supplier or a professional welding engineer