Nuclear industry welding materials

Nuclear industry welding materials:Welding Properties of Steel

● Nuclear industry welding materials Carbon Steel Welding Process Characteristics

Nuclear industry welding materials Carbon steel has a low carbon content and other alloying elements, and is high-quality carbon steel with strict control over harmful element content, resulting in superior weldability compared to other types of steel.

● Welding has the following characteristics:

① It can be assembled into a variety of joints, adapting to welding in various positions. The welding process and operating techniques are relatively simple and easy to master.

② Preheating is generally not required before welding. However, there are certain technical and quality assurance requirements for welded joints in nuclear island installation projects. Nuclear power plants are designed for 40 years of operation, and these joints must withstand various stresses (mechanical, thermal, and corrosion).

③ Good plasticity: The weld seam is less prone to cracking and porosity, making it suitable for the manufacture of large components and pressure vessels. Nuclear power plants use it to prefabricate supports, storage tanks, pipelines, etc.

④ Welding Power Source: When using manual arc welding, a DC welding machine is required, as basic electrodes are used in the project. When using argon arc welding, there are no specific requirements for the welding power source; DC welding can be used. ⑤ The weld pool may also be attacked by oxygen and nitrogen in the air, causing oxidation or nitridation of the weld metal. The presence of ferrous oxide in the weld may cause hot cracking. However, nuclear power projects place particular emphasis on selecting high-quality carbon steel electrodes, particularly those with good crack resistance and alkaline resistance. Technically, reliable welding methods and processes are employed, and welders involved in construction must undergo rigorous training and certification before taking up their posts.

⑥ Welding Methods: For low-carbon steel, almost any welding method can meet performance requirements. Welding methods used in nuclear island installation projects include argon arc welding, manual metal arc welding, argon arc welding, and CO₂ gas shielded welding.

★ Nuclear industry welding materials Characteristics of Stainless Steel Welding Processes

The vast majority of stainless steel welding involves austenitic stainless steel. Austenitic stainless steel offers excellent corrosion resistance, high-temperature resistance, and excellent weldability. However, improper welding materials or welding procedures can also lead to the following problems:

★ Intergranular corrosion is one of the most dangerous forms of damage to 18-8 austenitic steel (such as 1Cr18Ni9). The solubility of carbon in austenite at room temperature is minimal, about 0.02~0.03%, while the carbon content in general stainless steel exceeds 0.02~0.03. Therefore, carbon can only be dissolved in austenite in the quenched state, thereby ensuring that the steel has high chemical stability. However, when austenitic steel in this quenched state is heated to 450~850℃ or used for a long time at this temperature, intergranular corrosion will occur in the corrosive medium. Intergranular corrosion of austenitic steel is generally believed to be caused by the formation of a chromium-depleted layer at the grain boundary. The reason is that at a temperature of 450~850℃, the diffusion rate of carbon in austenite is greater than the diffusion rate of chromium in austenite. When the carbon content in austenite exceeds its solubility at room temperature (0.02~0.03%), carbon continues to diffuse to the austenite grain boundary and combines with chromium to precipitate chromium carbide Cr23C6. However, chromium’s atomic radius is large, so its diffusion rate is too slow to reach the boundaries. When a large amount of chromium near the grain boundaries reacts with carbon to form chromium carbide, the austenite boundaries become chromium-depleted. When the chromium content of the metal near the grain boundaries falls below 12%, the austenite loses its corrosion resistance. Intergranular corrosion occurs under the influence of corrosive media.

★Austenitic stainless steel can cause intergranular corrosion in the weld and heat-affected zone if welded improperly. Therefore, the following welding procedures should be implemented:

① Control the carbon content. Carbon is the primary element causing intergranular corrosion. When the carbon content is below 0.08%, the amount of carbon precipitated is low. When the carbon content exceeds 0.08%, the amount of carbon precipitated increases. Therefore, the carbon content of the base metal and welding consumables should be kept below 0.08%. Examples include 0Cr18Ni9Ti, A107, and A137. Furthermore, if the carbon content in austenitic steel is between 0.02% and 0.03%, all the carbon dissolves in the austenite. Even when heated to 450-850°C, no chromium-depleted zones form, preventing intergranular corrosion. Commonly known as ultra-low carbon stainless steels include 00Cr18Ni10.

② Add stabilizers such as Ti and Nb to the core welding consumables. Carbon combines with elements with a stronger affinity than chromium to form stable carbides, thus preventing chromium depletion at austenite grain boundaries and providing excellent resistance to intergranular corrosion. Commonly used stainless steels and welding consumables contain Ti and Nb.

③ Solution treat the weld joint. This involves heating the joint to 1050-1100°C after welding, allowing the carbon to dissolve back into the austenite. The joint is then rapidly cooled, stabilizing the austenite structure.

④ Adopt a duplex structure. Ferrite-forming elements such as chromium, aluminum, silicon, and molybdenum are added to the weld to create a duplex structure of austenite and ferrite.

⑤ Because chromium diffuses faster in ferrite than in austenite, chromium carbides precipitate within and near the ferrite, alleviating chromium depletion at the austenite grain boundaries. The ferrite content in the weld metal is generally controlled to 5-15%. Excessive ferrite can also make the weld metal brittle.

⑥ Reduce welding heat input. Regarding welding techniques, low welding current, high welding speed, and short-arc multi-pass welding can be used. After welding one layer, allow it to cool completely before welding the next layer. This is called interpass temperature control. When welding stainless steel, welders generally keep the interpass temperature below 60°C (allowing it to be touched by hand before welding the next layer). Furthermore, the welding sequence must be carefully considered to minimize repeated thermal cycling. Furthermore, care should be taken to avoid overheating of the weld (for example, a bluish color from a polished weld) or reddening of the electrode tail (due to excessive temperature). Premature volatilization of some useful protective components and burnout of alloying elements can also easily lead to welding defects.

Welding Material Management

Welding material management is a prerequisite for ensuring welding quality. Improper use of welding materials can lead to potentially substandard welds, leaving quality risks and even causing major accidents during nuclear power plant operation.

Welding material management is primarily addressed from two perspectives:

1) External Assurance:

a) Qualified suppliers must be evaluated.

b) Externally procured welding materials must be purchased and inspected according to standards or (design) welding procurement specifications. Nuclear-grade welding materials, in particular, must undergo re-inspection and pass inspection according to acceptance and testing procedures before they can be stored.

2) Internal Control: Storage, drying, insulation, and distribution must be strictly performed according to procedures.

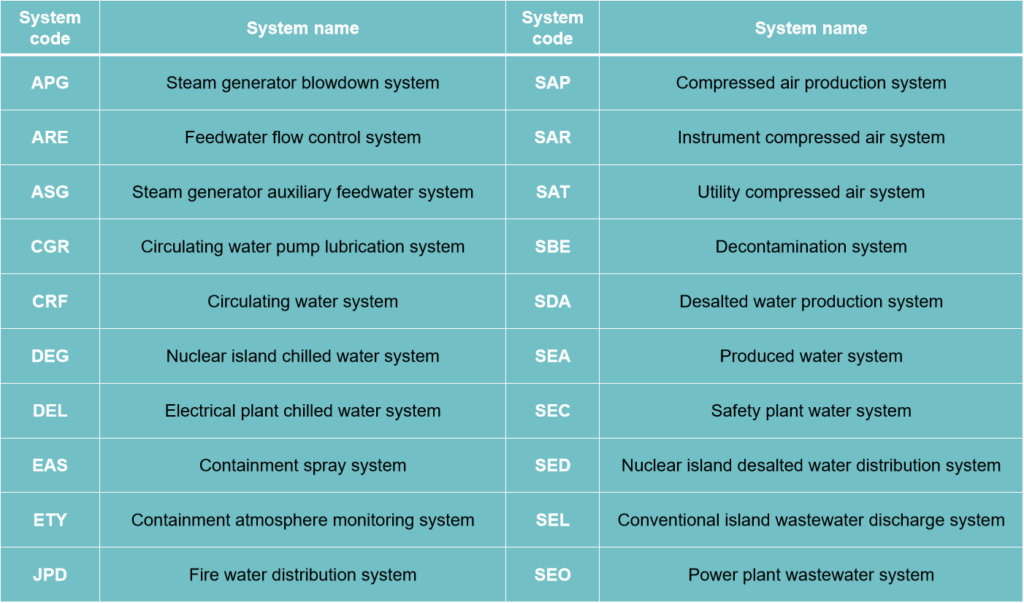

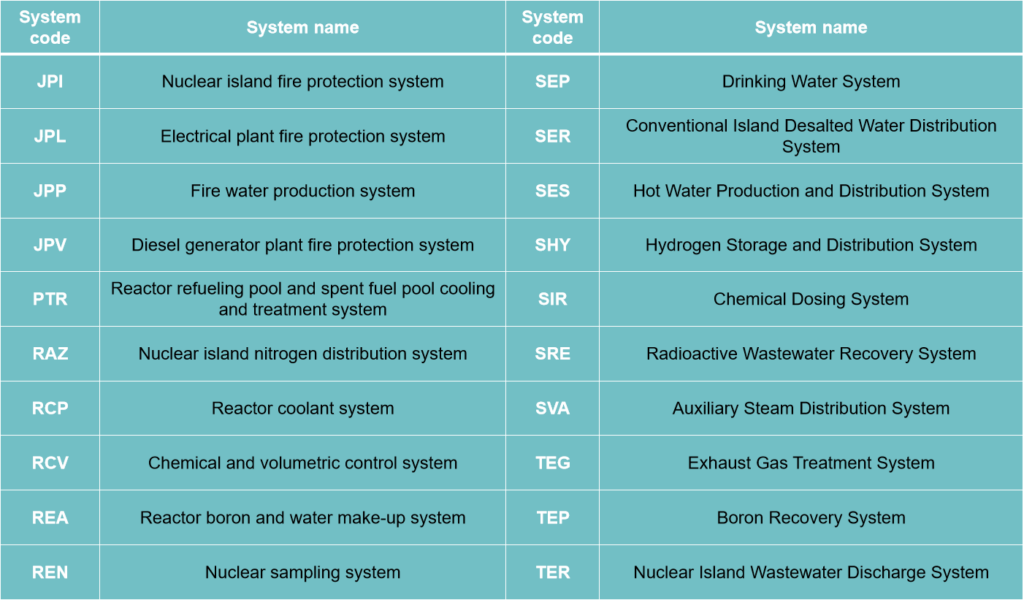

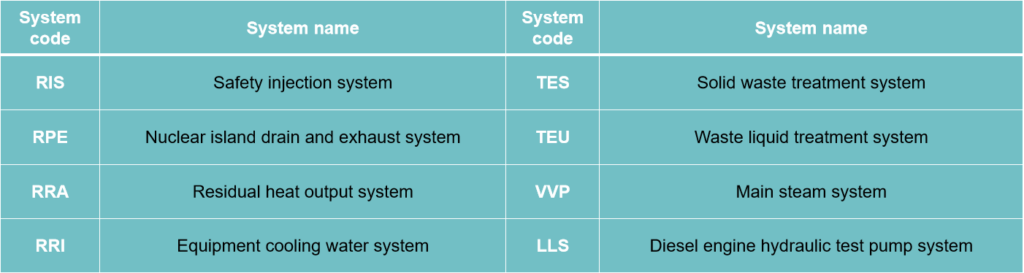

List of pressurized water reactor nuclear power plant systems (including nuclear steam systems)

Conventional island welding projects

Major systems involved include main steam, main feedwater and startup feedwater, bypass, high-pressure heater circuits, circulating water, condensate, heater drains, exhaust, auxiliary steam, condenser vacuum pumping, turbine-generator lubricating oil, condensate polishing, and secondary circuit sampling systems. These projects involved welding the main steam piping, steam guide pipes, reheat steam piping (cold and hot sections), main feedwater piping, extraction steam piping, oil system piping, stainless steel piping, thermal instrumentation and sewage sampling pipes, water tanks, circulating water piping, oil tanks, deaerators, low-pressure cylinders, condenser assembly welding, aluminum busbars, and other key load-bearing components. Over 100,000 welds were required, with a significant amount of thick alloy steel pipes being welded. The welding process required preheating, interpass insulation, post-heating, post-weld heat treatment, and anti-deformation measures. Due to the limited space available for the designed piping layout and the narrow welding space, welding joints was challenging.

During nuclear power plant operation, the main steam drives the turbine generators to generate electricity, then converts into condensate, which flows into the condenser. At this point, the condenser water temperature is very high, approximately 200°C, requiring cooling. The circulating cooling water system (three-circuit system) provides the necessary cooling water for the turbine generator condenser and auxiliary cooling water system. The circulating water cooling system is sourced from seawater. 39.77 cubic meters of water is drawn from the intake at a rate of 3 meters per second and flows into the water transfer tunnel at a flow rate of 3 meters per second. It then passes through a trash rack, a mechanical screen remover, and a drum-shaped rotary filter before entering a circulating water pump (concrete volute pump). The seawater is then transported to the turbine generator condenser for cooling. The cooled seawater then flows out to the sea through a drainage pipe. This pipe is made of a special material resistant to seawater corrosion: 10CrMoAl.Pipelines with diameters exceeding 4 meters typically require extensive welding and high quality standards. This is a concealed project, requiring extensive nondestructive testing.