Martensitic stainless steels welding are a type of stainless steel whose mechanical properties (such as hardness and strength) can be significantly modified through heat treatment (such as quenching and tempering). They are members of the stainless steel family known for their strength and hardness.Martensitic Stainless Steel Welding

Key Characteristics:

1. Microstructure: Their name derives from their primary microstructure—martensite. This structure, formed by rapidly cooling (quenching) austenite at high temperatures, is a supersaturated solid solution with a body-centered cubic structure, which is the fundamental reason for their high strength and hardness.

2. Chemical Composition:

● Chromium Content: Typically between 11.5% and 18%. Chromium is a key element in providing “stainless” properties, forming a passive film on the surface that resists corrosion.

● Carbon Content: Relatively high, typically between 0.1% and 1.2%. Carbon is essential for the formation of martensite. Higher carbon contents result in greater hardness and strength after quenching, but typically at the expense of some toughness and corrosion resistance.

● Other Elements: Typically contains little or no nickel (a key difference from austenitic stainless steel). Elements such as molybdenum and vanadium are sometimes added to improve certain properties.

Main Performance Characteristics:

Advantages:

● High strength and hardness: These are its most prominent advantages. After proper heat treatment, its strength and hardness can be significantly higher than other types of stainless steel, even reaching very high levels.

● Good wear resistance: High hardness naturally results in excellent wear resistance.

● Moderate cost: Since it contains little or no precious metal nickel, its cost is generally lower than that of austenitic stainless steel.

● Properties can be adjusted through heat treatment: By varying the quenching and tempering process parameters, the combination of strength, hardness, and toughness can be adjusted over a wide range to meet different application requirements.

● Moderate corrosion resistance: It offers good corrosion resistance in mild environments (such as air, steam, fresh water, and certain chemicals). It is superior to carbon steel but inferior to austenitic and ferritic stainless steels.

Disadvantages:

● Relatively poor corrosion resistance: It is susceptible to pitting and stress corrosion cracking, particularly in chloride environments. Its corrosion resistance is the lowest among all stainless steel types.

● Poor weldability: During welding, a hard and brittle structure easily forms in the heat-affected zone, increasing cracking susceptibility. Therefore, strict preheating and post-heating processes are required.

● Low toughness: Especially at high hardness, its plasticity and impact toughness are poor.

Common grades and applications:

● 410 (1.4006): The most basic and commonly used martensitic stainless steel. It offers good overall mechanical properties and moderate corrosion resistance.

▶ Applications: Widely used in applications requiring both strength and corrosion resistance, such as valves, pump parts, shafts, bolts, nuts, cutlery, and surgical instruments.

● 420 (1.4021 / 1.4028): Its carbon content is higher than 410 (approximately 0.15% or more), resulting in higher hardness and wear resistance after quenching, but slightly lower corrosion resistance.

▶ Applications: Primarily used in the manufacture of knives, cutting tools, measuring tools, bearings, nozzles, and valve seats. Many common stainless steel table knives and scissors are made from 420 steel.

●440 Series (440A, 440B, 440C): High-carbon, high-chromium martensitic stainless steels. 440C, in particular, boasts a carbon content of 0.95-1.20%, making it one of the hardest stainless steels and offering excellent wear resistance, but also relatively poor toughness.

▶Applications: Primarily used in applications requiring extremely high hardness and wear resistance, such as high-end cutting tools, bearings, surgical blades, and molds.

●431 (1.4057): Adds nickel to chromium, improving corrosion resistance and toughness while maintaining high strength.

▶Applications: Used for high-strength parts requiring good corrosion resistance, such as aircraft engine components and pump shafts.

●420J2 and 420F: Free-machining martensitic stainless steels with sulfur or selenium added to improve machinability.

▶Applications: Suitable for parts machined on a large number of automatic lathes, such as screws and bushings.

Heat Treatment Process:

The properties of martensitic stainless steel are greatly dependent on heat treatment, which primarily includes the following:

● Annealing: This process reduces hardness and facilitates machining.

● Quenching: Heating to high temperatures (e.g., 980-1050°C) dissolves carbides, forming austenite. Rapid cooling (either oil quenching or air cooling) transforms the material into martensite, achieving high hardness.

● Tempering: The quenched material is very hard but brittle, requiring tempering (usually between 150-700°C) to reduce internal stresses and adjust the balance between toughness, strength, and hardness. Importantly, martensitic stainless steel should be tempered away from the brittle zone of 475°C to prevent a sharp drop in toughness.

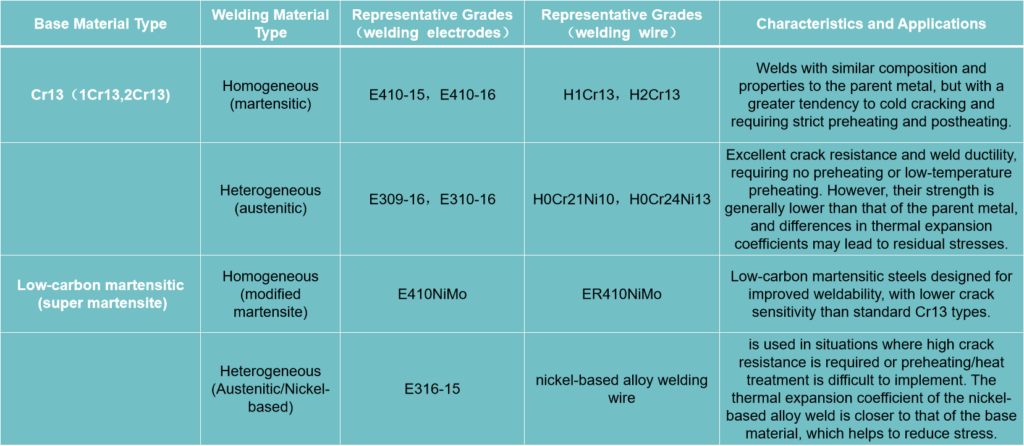

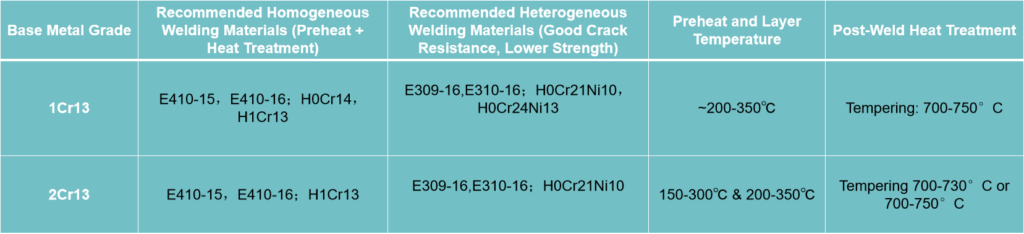

Welding consumables for martensitic stainless steel are primarily categorized as homogeneous (matching the base material) and heterogeneous (austenitic or nickel-based). When selecting a consumable, consider the weld performance requirements (strength, corrosion resistance), process conditions (preheating, heat treatment possibilities), and cost.

Selection Strategies:

● For welds with equal strength and corrosion resistance to the base material, and for those that can undergo rigorous preheating and post-weld heat treatment: homogeneous welding consumables can be selected.

● For complex structures, high constraints, where preheating or post-weld heat treatment is not possible, and where crack resistance and ductility are of primary concern: heterogeneous austenitic or nickel-based welding consumables should be selected.

Major Welding Issues and Countermeasures:

When welding martensitic stainless steel, there are two issues that require special attention:

● Cold cracking (especially hydrogen-induced delayed cracking): This presents the greatest risk.

▶ Causes: The weld and heat-affected zone (HAZ) are prone to forming a hard and brittle martensitic structure; hydrogen intrusion (from moisture in the weld material, oil contamination, and ambient humidity); and high weld restraint stress.

▶ Countermeasures:

① Strict preheating and layer temperature control: This is the most critical process measure. The preheat temperature is typically between 150-450°C, depending on the carbon content of the steel and the degree of component restraint.

② Use low-hydrogen welding consumables and processes: Select basic welding rods and dry them according to specifications (e.g., 350-400°C). Using argon arc welding or argon-enriched gas shielded welding can help reduce hydrogen sources.

③ Post-weld heat treatment: Promptly perform high-temperature tempering (generally at 650-750°C) to relieve stress, diffuse hydrogen, and improve the structure.

④ Control weld composition: Strictly limit the content of impurities such as S and P.

● Heat-Affected Zone (HAZ) Brittleness:

▶ Cause: Welding thermal cycles may cause HAZ grain coarsening, forming coarse martensite or ferrite + carbides, reducing plasticity and toughness.

▶ Countermeasures: Control heat input and cooling rate, avoid excessive preheat temperatures (to prevent brittleness at 475°C), and optimize welding process parameters.

Key Points in Welding Process:

Successful welding requires comprehensive process assurance:

● Pre-weld Preparation: Thoroughly clean the groove and both sides of the groove from oil, water, rust, and other contaminants to reduce hydrogen sources.

● Preheating and Pass Temperature: Preheating is required. The preheating temperature depends on the material’s carbon content and thickness (for example, for carbon content of 0.1% to 0.2%, preheat to approximately 200-260°C). When performing multi-pass welding, the interpass temperature must be maintained at or above the preheating temperature.

● Welding Methods:

▶ Arc welding: The most commonly used and highly flexible.

▶ Tungsten Inert Gas Welding (TIG): Commonly used for root welding of thin plates, pipes, and critical components, it offers high quality and aesthetically pleasing results.

▶ Metal Inert Gas Welding (MIG/MAG): An argon-rich gas mixture (such as Ar + CO₂) can be used, offering high efficiency and low hydrogen content, which helps reduce cold crack susceptibility.

● Post-weld Heat Treatment:

▶ Tempering: The most common process involves a temperature of 650-750°C, followed by holding and air cooling. This process aims to reduce hardness, relieve stresses, and improve toughness.

▶ Complete Heat Treatment: For quenched and tempered steel welded in the annealed state, a post-weld quenching and tempering process is required to achieve optimal properties.

● Important Note: Tempering should generally not be performed immediately after welding. It is recommended to slowly cool to 100-200°C and hold for a period of time after welding to allow the austenite in the weld and HAZ to fully transform into martensite before tempering. This prevents the austenite from decomposing into coarse structures or carbide precipitation, which can lead to embrittlement.

Summary and reminders:

When welding martensitic stainless steel, the key is to prevent and control cold cracking and embrittlement. Remember the following key points:

● Careful material selection: Choose homogeneous or heterogeneous welding consumables based on your primary requirements for weld performance and process conditions.

● Strict hydrogen control: From consumable storage and drying to groove cleaning, every step must be meticulous.

● Temperature is critical: Controlling preheating, layer temperature, and post-weld heat treatment parameters is crucial and should not be haphazard.

● For complex or critical components: Before welding production components, performing a welding procedure qualification (WPS/PQR) is essential to ensure quality and reduce risk.