Choosing the right shielding gas for aluminum welding is crucial for achieving high-quality welds. Below, I’ll explain in detail how to choose the right shielding gas, including the characteristics of different gases, applicable scenarios, and the selection process.

一: Shielding Gas for Aluminum Welding:

① Anti-oxidation: Aluminum reacts easily with oxygen in the air at high temperatures, forming high-melting-point aluminum oxide (Al₂O₃), which can lead to weld inclusions, incomplete fusion, and porosity.

② Arc Stabilization: The right gas helps stabilize arc combustion, reduce spatter, and improve weld formation.

③ Influencing Weld Penetration and Appearance: The thermophysical properties of different gases directly affect weld penetration, width, and surface gloss.

二: Common Shielding Gas Types and Characteristics

The most commonly used shielding gases for aluminum welding are inert gases, as they do not chemically react with aluminum. Primarily argon (Ar) and helium (He), as well as their mixtures.

① Pure argon (100% Ar): This is the most common and versatile choice, particularly suitable for TIG and MIG welding of thin and medium-thick plates.

● Advantages:

▶ Excellent arc stability: The arc is soft and stable, making it particularly suitable for the precise control of TIG welding and the short-circuiting transition of MIG welding.

▶ Excellent cathode atomization (cleaning effect): In AC TIG welding or MIG welding (with an AC component), argon effectively removes the oxide film on the aluminum surface, exposing clean metal.

▶ Lower cost: Cheaper and more readily available than helium.

▶ Beautiful weld appearance: The weld is well-formed and has a smooth, clean surface.

● Disadvantages:

▶ Low heat input: This results in shallower and wider weld penetration.

● Suitable applications:

▶ TIG welding of all plate thicknesses (especially AC TIG).

▶ MIG welding of thin and medium-thick plates (thickness ≤ 25mm).

▶ Manual welding and all general applications.

② Pure helium (100% He): Helium is not typically used as a standalone gas, but rather mixed with argon. However, pure helium is used in certain automated applications.

● Advantages:

▶ High heat input: The high voltage of the helium arc generates greater heat input, resulting in deeper and narrower weld penetration.

▶ Increased welding speed: The high heat input allows for faster welding in automated welding.

● Disadvantages:

▶ Arc instability: The arc “diversifies,” making it difficult to control and unsuitable for manual welding.

▶ Weak cathode atomization: Ineffective in removing oxide films.

▶ High cost: Helium is much more expensive than argon.

● Applicable Applications:

▶ High-speed automated MIG welding (for thick plates).

▶ Specific applications requiring extremely high weld penetration.

③ Argon-helium mixture (Ar + He): This is the optimal solution combining the advantages of both gases and is widely used in MIG welding of thick plates and high-speed welding.

● Common mixture ratios:

▶ 75% Ar + 25% He: A very common mixture ratio that improves heat input and weld penetration while maintaining good arc stability. Suitable for medium and thick plates.

▶50% Ar + 50% He: Further improves heat input and penetration, suitable for thicker plates.

▶25% Ar + 75% He: Appears to have properties close to pure helium, suitable for applications requiring extremely high heat input, such as welding ultra-thick aluminum plates.

●Advantages:

▶Combines the stability of argon with the high heat input and deep penetration of helium.

▶Increased welding productivity.

▶Reduces porosity (because the weld pool is more fluid, allowing gases to escape more easily).

●Applicable Applications:

▶MIG welding of medium to thick aluminum plates (>12mm).

▶Automatic or mechanized welding.

▶Applications requiring high welding speeds and deep penetration.

④Argon-Hydrogen Mixture (Ar + H₂): Important Note: This mixture is only used for TIG welding and should never be used for MIG welding! Hydrogen in the weld pool can cause porosity and hydrogen embrittlement.

● Advantages:

▶ Enhanced Reducibility: Hydrogen has a reducing effect, further improving oxide film removal.

▶ Higher Thermal Conductivity: Increased heat input slightly increases weld penetration.

▶ Brighter, more aesthetically pleasing welds: Particularly suitable for applications requiring extremely high weld appearance, such as food processing and aerospace.

● Common Ratios:

▶Hydrogen is typically added in small amounts, typically 1% to 5%. Exceeding 5% can create a risk of porosity.

● Applicable Applications:

▶ Automatic TIG welding where weld quality and appearance are extremely demanding.

▶ Caution is advised when welding 5xxx series aluminum alloys with high magnesium content, as porosity may occur.

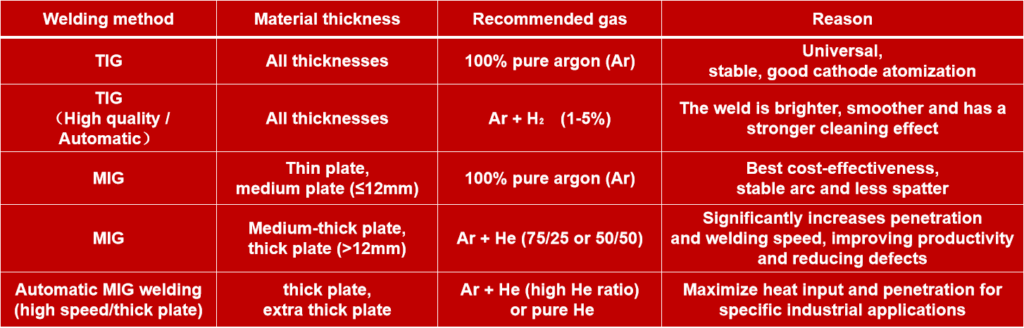

Summary and Final Recommendations

Final Reminder:

● Gas Purity is Critical: When welding aluminum, a high-purity shielding gas (typically above 99.996%) must be used. Any moisture or impurities can directly lead to porosity.

● Maintain an appropriate gas flow rate: Typically, TIG welding uses 10-15 L/min, while MIG welding uses around 18-25 L/min, depending on nozzle size, welding environment, and welding current.

● Start with pure argon: If you’re a beginner or unsure, it’s always a good idea to start with 100% pure argon. If you encounter issues with penetration or efficiency, consider upgrading to an argon-helium mixture.