Heat-resistant steel submerged arc welding wire

Heat-resistant steel SAW is a welding material specifically designed for welding components operating at high temperatures (such as power plant boilers, pressure vessels, and pipelines). Its core objective is to ensure that the weld exhibits stable mechanical properties, excellent creep resistance, and good oxidation resistance at high temperatures.Heat-resistant steel submerged arc welding wire

一. Selection Guide for Heat-Resistant Steel Submerged Arc Welding Wire

The selection of heat-resistant steel submerged arc welding wire strictly follows the principle of “equal composition matching,” meaning that the chemical composition of the welding wire must be similar to that of the base metal to ensure that the performance of the weld at high temperatures remains consistent with that of the base metal.

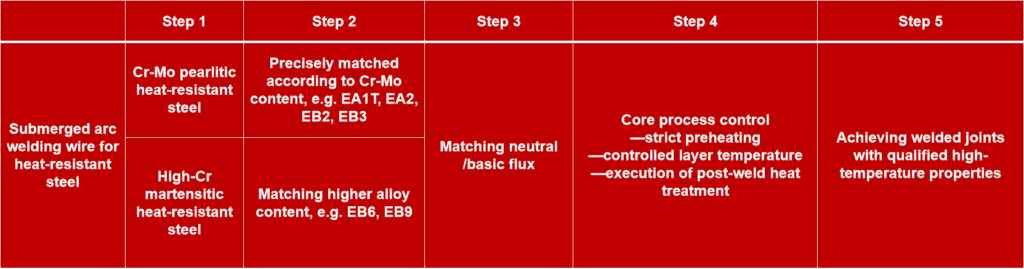

To more intuitively understand the selection logic, you can refer to the flowchart below:

II. Common Types and Models of Heat-Resistant Steel Submerged Arc Welding Wire

❶ Low Chromium-Molybdenum Steel (Pearlitic Heat-Resistant Steel) Welding Wire

This is the most widely used type, commonly used in working environments below 550℃.

●EA1T / EA1: Used for welding 0.5Mo steel (such as P1/T1).

●EA2 / H08MnMoA: Used for welding 0.5Cr-0.5Mo steel (e.g., P2/T2).

●EB2 / H08CrMnSiMo: Used for welding 1.25Cr-0.5Mo steel (e.g., P11/T11, P12/T12).

View EB2 Detailed Data:https://www.akweld.com/wp-content/uploads/2025/08/EB2.pdf

●EB3 / H10Mn2NiMoA: Used for welding 2.25Cr-1Mo steel (e.g., P22/T22, P23/T23). This is a very common combination used in power plant boilers.

❷ Medium-high chromium-molybdenum steel (martensitic heat-resistant steel) welding wire

Used in higher temperature (up to 650℃) and more corrosive environments.

●EB6: Used for welding 5Cr-0.5Mo steel (e.g., P5/T5).

●EB9 / H08Cr9MoMnV: Used for welding 9Cr-1Mo steel (such as P9/T9, P91/T91).

●Special Welding Wire: For high-alloy steels used in ultra-supercritical units such as T/P92 and T/P122, there are special welding wires with more complex compositions (usually containing elements such as W, V, Nb, and B).

Please note: The above models mainly follow AWS A5.23/ASME SFA-5.23 standards.

III: Core Points of Welding Process

Welding heat-resistant steel is much more complex than welding ordinary carbon steel, and the following aspects must be strictly controlled:

❶ Strict Pre-Welding Cleaning

Oil, water, rust, and other impurities must be thoroughly removed from the bevel and both sides to prevent hydrogen-induced cracking.

❷ Preheating and Interpass Temperature Control

● Preheating: Mandatory! Preheating specifications must be strictly followed according to the alloy content and thickness of the steel (e.g., P91 steel typically requires 200-250℃).

● Interpass Temperature: Throughout the welding process, the interpass temperature must be monitored and ensured to be no lower than the preheating temperature and not exceed the limit (usually there is an upper limit requirement).

❸ Selecting a Suitable Flux and Controlling Heat Input

● Flux Matching: Alkaline sintered flux is recommended to obtain welds with high purity and excellent mechanical properties, especially high toughness.

● Heat Input Control: Use medium or low heat input to avoid coarse weld grains, which affect high-temperature toughness.

❹ Post-Weld Heat Treatment

● Its purpose is to:

⑴ Eliminate residual welding stress.

⑵ Improve the microstructure of the weld and heat-affected zone.

⑶ Allow hydrogen to escape, preventing delayed cracking.

● Heat treatment processes (such as temperature and time) must be strictly followed according to regulations.

Hopefully, this systematic introduction will help you fully understand heat-resistant steel submerged arc welding wire. If you can provide specific base material models (such as P91, P22, etc.) and working conditions, I can provide you with more specific selection and process suggestions.