High-strength steel submerged arc welding wire

High-strength steel submerged arc welding wire is a welding material specifically designed for welding low-alloy high-strength structural steels with yield strength typically above 490 MPa (approximately 70 ksi). Its core objective is to ensure that the weld metal achieves high strength matching the base metal while possessing excellent low-temperature impact toughness and good crack resistance.High-strength steel submerged arc welding wire (SAW)

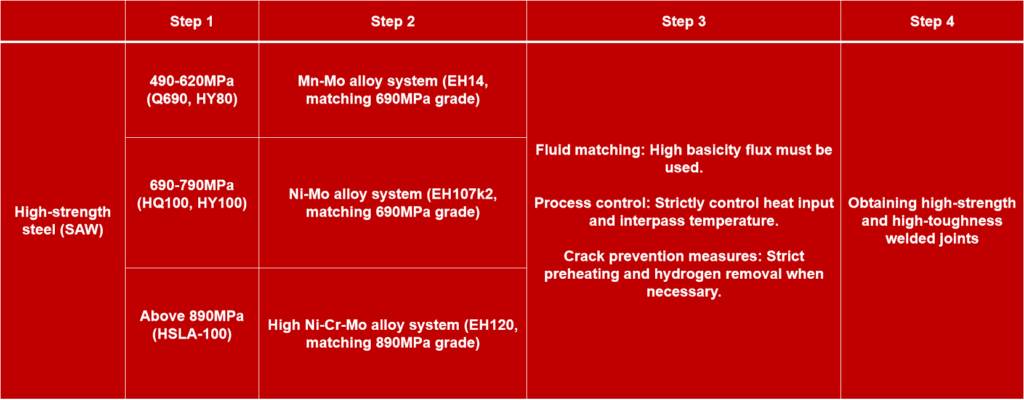

一. High-Strength Steel Submerged Arc Welding Wire Selection Guide

Selecting high-strength steel submerged arc welding wire is a systematic process, and its selection logic can be summarized as follows:

二. Common Types and Models of High-Strength Steel Submerged Arc Welding Wire

Based on the selection path shown above, the following are some common wire types and models (mainly following AWS A5.23 standards):

❶ 490-620 MPa (70-90 ksi) Strength Grade Welding Wire

This is a widely used grade, commonly used in engineering machinery, shipbuilding, and building structures.

(1) EH14: A Mn-Mo alloy welding wire, commonly used for welding Q690 (yield strength 690MPa/100ksi) grade steel. It is one of the mainstream choices for welding this grade of steel.

(2) Other systems: Depending on different toughness and crack resistance requirements, microalloying systems such as Mn-Ni-Mo may also be used.

❷ 690-790 MPa (100-115 ksi) strength grade welding wire

This grade requires higher toughness and strength in the weld, usually achieved by adding nickel (Ni).

(1) EH107K2: A typical Ni-Mo alloy welding wire, used for welding high-strength steels in the 690-790MPa range, such as HY80 and HQ100. The addition of nickel significantly improves the low-temperature toughness of the weld.

❸ Welding wires with strength levels of 890 MPa (130 ksi) and above

Used for welding structural steels with the highest strength levels, such as armor steel and deep-sea submersible hulls.

⑴ EH120: A high Ni-Cr-Mo alloy welding wire used for welding steels with strength levels of 890 MPa and above, such as HSLA-100. Its complex composition is designed to simultaneously ensure ultra-high strength and sufficient toughness reserve.

Please note:

⑴ The above models are welding wire models (such as the “EXXTX” series in AWS A5.23). In practical applications, they must be used with a suitable flux.

⑵ The number after “EH” usually indicates the minimum tensile strength (in ksi) achievable with this wire-flux combination. For example, EH14 is approximately 140 ksi (approximately 965 MPa), but this is the result after flux matching.

三. Core Points of Welding Process

Welding high-strength steel is much more demanding than welding ordinary carbon steel. The following aspects must be strictly controlled to prevent weld performance degradation and cracking:

❶ Flux Selection and Management

⑴ High-basicity sintered flux must be used: This is crucial for obtaining high-toughness welds. Basic flux effectively reduces oxygen content and impurities in the weld, significantly improving impact toughness.

⑵ Strict moisture prevention: The flux must be dried according to regulations before use to prevent hydrogen-induced cracking.

❷ Strict control of welding heat input

⑴ Use medium or low heat input.

⑵ Excessive heat input will lead to coarse weld grains, severely reducing strength and toughness.

⑶ Heat input should be strictly controlled within the range determined by the process qualification.

❸ Control of preheating and interpass temperature

⑴ Preheating: This is mandatory! Preheating specifications must be strictly followed based on the carbon equivalent, plate thickness, and restraint of the steel grade to prevent cold cracking.

(2) Interpass Temperature: Monitor and ensure the interpass temperature is not lower than the preheating temperature and does not exceed the upper limit (usually 200-250℃) to avoid weld overheating.

❹ Focus on Hydrogen-Induced Cracking and Post-Weld Treatment

(1) Strict Low-Carbon Stiffness Management: All welding materials (welding wire, flux) must be dry, and the bevel must be thoroughly cleaned to eliminate hydrogen sources at the source.

(2) Post-Weld Hydrogen Removal Treatment: For thick plates or ultra-high-strength steel, immediate post-weld hydrogen removal treatment is an effective means of preventing delayed cracking.

(3) Post-Weld Heat Treatment: Determine whether post-weld heat treatment is necessary to relieve stress or improve performance based on material and technical requirements.

Hopefully, this systematic introduction will help you fully understand high-strength steel submerged arc welding wire. If you can provide specific base metal models (such as Q690, HQ100, etc.) and working conditions, I can provide you with more specific selection and process suggestions.