Robotic automated welding

In robotic automated welding, because the process is programmed, continuous, and without real-time human intervention, the requirements for the characteristics of the welding wire are far more stringent than in manual welding.Robotic automated welding

Generally speaking, the core requirements can be summarized as “consistency” and “predictability.” Robots cannot adjust in real time through feel or sight like skilled welders, so every characteristic of the welding wire must be highly stable to ensure a smooth welding process and uniform weld quality.

The following are the specific aspects of the higher requirements placed on welding wire in robotic automated welding:

一. Robotic automated welding:Physical Characteristics

❶ Wire Feeding Performance

This is the most core and critical requirement. Poor wire feeding will directly lead to welding interruptions, unstable arcs, and welding defects.

⑴ Straightness: The welding wire must be extremely straight. Any bends or spirals (“elephant trunk bends”) will create enormous resistance in the wire feeding hose, leading to unstable wire feeding, vibration, or even jamming. This problem is amplified during high-speed robotic welding.

⑵ Diameter Tolerance: The diameter of the welding wire must be highly uniform, with a very small tolerance range. Small changes in diameter can lead to:

● Unstable wire feed speed (because the wire feeder feeds wire by length, changes in cross-sectional area result in changes in the actual amount of deposited metal).

● Current fluctuations, affecting arc stability and penetration depth.

⑶ Surface Quality:

● Smoothness: The surface must be smooth with a low coefficient of friction to reduce wire feed resistance.

● Cleanliness: The surface should be free of oil, scale, dust, and other impurities. These impurities can contaminate the arc and molten pool, leading to porosity, slag inclusions, and clogging of the contact tip.

● Coating Uniformity: Copper-plated welding wire is common; the coating must be uniform and have strong adhesion. Coating peeling can clog the wire guide tube and contact tip, increasing wire feed resistance and affecting conductivity.

❷ Mechanical Properties

⑴ Hardness/Rigidity: The welding wire needs a certain degree of rigidity. Wires that are too soft (such as some aluminum welding wires or flux-cored welding wires) are prone to bending and folding during feeding, causing wire feed problems.

(2) Waist/Pitch: For coiled welding wire, the natural curvature (waist) after release from the coil must be controlled within a certain range. Excessive wedge will affect the accuracy of the arc direction and interfere with the gas shielding effect.

二. Robotic automated welding:Chemical and Metallurgical Properties

❶ Chemical Composition Uniformity

The chemical composition of the entire coil and batch of welding wire must be highly consistent. Fluctuations in chemical composition will directly lead to:

⑴ Unstable mechanical properties (strength, toughness) of the weld metal.

⑵ Changes in welding metallurgical behavior, affecting crack resistance, corrosion resistance, etc.

⑶ Inconsistent weld appearance color (especially in stainless steel and aluminum welding).

❷ Cleanliness and Low Defect Rate

Non-metallic inclusions, porosity, and other defects inside the welding wire must be extremely low. During high-speed robotic welding, these internal defects will directly transfer to the weld, forming slag inclusions or porosity, which are difficult to detect through visual inspection.

三. Robotic automated welding:Process Performance

❶ Arc Stability

Robotic welding aims for “what you set is what you get.” The welding wire must provide an extremely smooth and stable arc under the set parameters. Frequent arc flashes and bursts are absolutely unacceptable in automated welding, as they directly lead to substandard product quality.

❷ Droplet Transfer Pattern

The welding wire should be designed to facilitate the desired droplet transfer pattern (e.g., spray transfer, pulse transfer). This transfer must be controllable and consistent to ensure minimal spatter and aesthetically pleasing weld formation.

❸ Spatter Rate

Low spatter is an important economic and quality indicator for robotic welding. High spatter will:

⑴ Contaminate the workpiece, welding torch, and robot body, increasing cleaning and maintenance costs.

⑵ Clog gas nozzles, affecting shielding effectiveness.

⑶ May adhere to the robot arm, causing damage.

❹ Weld Formation

The welding wire’s process characteristics should enable the formation of a smooth, flat weld that seamlessly transitions with the base material, reducing the workload of subsequent grinding.

四. Robotic automated welding:Packaging and Supply Forms

❶ Packaging Methods

⑴ Drum-packaged welding wire: This is the preferred choice for modern robotic welding. It fundamentally eliminates the “warping” problem, ensuring a smooth wire feeding path and low resistance, making it ideal for long-distance, high-speed wire feeding.

⑵ Coil-packaged welding wire: If used, ensure smooth wire feeding without jamming.

❷ Coil weight and joints

Using large-coil welding wire (e.g., 300kg, 500kg drums) reduces changeover frequency and improves equipment utilization. The number of joints inside the welding wire should be minimized, and the joints must be smooth, secure, and able to pass smoothly through the wire feeding system. A defective joint can cause production line downtime.

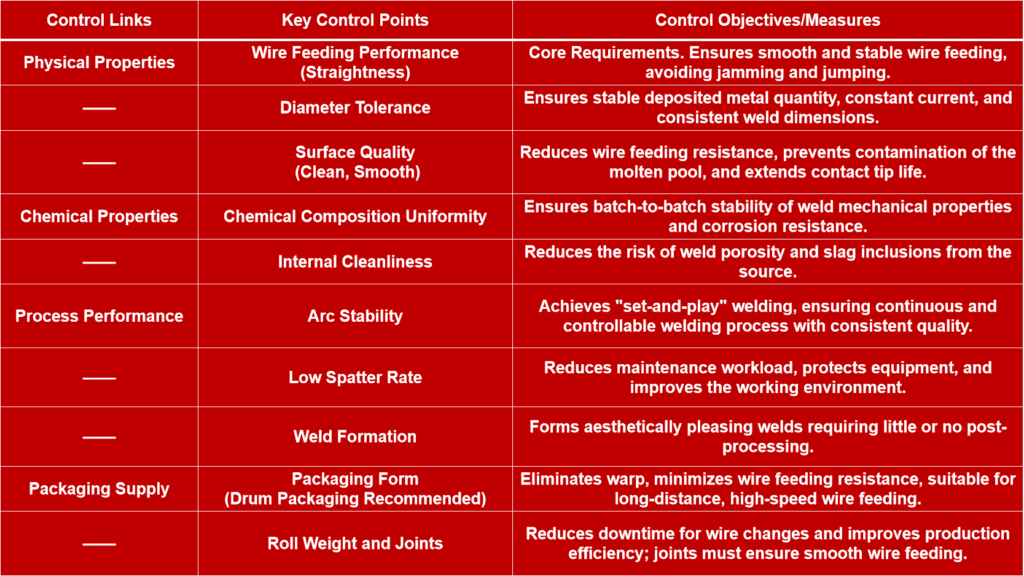

五. Summary and Comparison Table

六. Conclusion:

When selecting welding wire for robotic automated welding, one should not only focus on whether its chemical composition meets standards, but also prioritize its physical properties, process stability, and packaging. Always choose reputable brands and products specifically designed for automated applications and subject to rigorous quality control (e.g., “Robotics Grade” or “Automation Grade” certification). Investing in high-quality welding wire will bring production stability, reduced defect rates, and lower equipment maintenance costs, far outweighing the price difference itself.