aluminum alloy welding materials

aluminum alloy welding materials (welding wire) is a highly technical task, directly impacting the strength, corrosion resistance, crack resistance, and appearance of the weld joint. The following six key factors will systematically guide you in making the right choice.

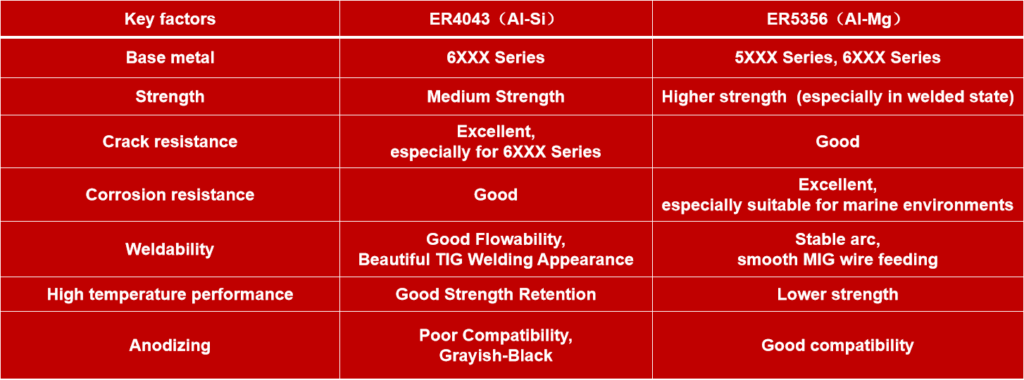

1. aluminum alloy welding materials:Base Metal Alloy Grade (The Most Critical Factor)

The primary consideration for selecting a aluminum alloy welding materials is the base material (parent metal) you are welding. The goal is to select a filler metal that has a chemical composition close to that of the parent metal but improves the properties of the weld metal after melting.

① Basic Principle: Refer to the filler metal selection chart recommended by the parent metal supplier or welding association (such as AWS). This is the most reliable method.

② Common Pairing Examples:

● Welding 6061 alloy: ER4043 or ER5356 are generally preferred.

● Welding 5052 alloy: ER5356 or ER5183 must be used. Using ER4043 will result in a mismatched weld chemistry and reduced performance.

● Welding 3003 alloy: ER1100 is typically used.

● Welding castings (such as A356): ER4043 is typically used.

2. aluminum alloy welding materials:Service and performance requirements for the weld

What environment will the weld be used in? What will it be subjected to?

① Strength requirements:

● ER5356: The weld strength it provides is generally higher than ER4043, especially when welding non-heat-treatable strengthened aluminum (such as the 5xxx series).

● ER4043: Slightly lower in strength, but with better fluidity and a better welding experience.

② Ductility and toughness:

● ER5356: Has better ductility and is suitable for structures subject to impact or vibration.

③ Anodizing:

● If anodizing is required after the workpiece is finished, ensure that the weld color matches the base metal. After anodizing, ER4043 welds appear dark gray, significantly different from the base metal. While ER5356 provides a relatively good match, subtle differences may still occur. For parts with extremely high appearance requirements, testing is required.

④ High-Temperature Service:

● ER4043 maintains better strength than ER5356 at temperatures above 65°C. ER5356 may soften at high temperatures due to the precipitation of the Mg2Si phase.

3. Crack Resistance

Hot cracking (solidification cracking) is a major concern when welding aluminum.

① The Role of Silicon (Si): ER4043 (5% Si content) exhibits excellent hot cracking resistance. This is because silicon forms a large amount of low-melting-point eutectic, which “heals” cracks between grain boundaries during weld solidification.

② Application Scenario: When welding heat-treatable alloys (such as the 6xxx series) or alloys with high crack sensitivity, ER4043 is the preferred choice because it effectively prevents hot cracking. For non-heat-treatable alloys (such as the 5xxx series), which inherently have better crack resistance, the matching ER5356 is more commonly used.

4. Corrosion Resistance

The corrosion resistance of the weld must match that of the base metal, especially in marine environments or chemical applications.

① Principle: The electrode potential of the weld should be as close as possible to that of the base metal to avoid electrochemical corrosion (galvanic corrosion).

② The Role of Magnesium (Mg): 5xxx series aluminum-magnesium alloys (such as 5052) inherently possess excellent corrosion resistance. Using high-magnesium welding wires such as ER5356 (containing 5% Mg) can maintain the corrosion resistance of the weld.

③ Note: If ER4043 (containing silicon) welding wire is used to weld 5xxx series base metals, the silicon element will cause the weld to develop a different microstructure, potentially reducing its corrosion resistance, especially its resistance to stress corrosion cracking, compared to the base metal.

5. Welding Method and Operating Characteristics

Different welding methods require different welding wire properties.

① MIG welding (metal inert gas welding):

● Typically uses thicker wire diameters (e.g., 0.8mm, 1.0mm, 1.2mm).

● ER5356: Offers a more stable arc and better wire feedability, making it a common choice for MIG welding.

● ER4043: Offers better flowability, a wetter weld pool, and easier wetting of the weld edge, but wire feedability may be slightly less stable than 5356.

② TIG welding (tungsten inert gas welding):

● Requires higher wire flowability and weld appearance.

● ER4043: Due to its excellent flowability and smooth weld appearance, it is very popular in TIG welding, especially for workpieces requiring a high level of aesthetics.

● ER5356: Can also be used for TIG welding, resulting in a stiffer weld with a sharper outline.

6. Post-weld processing

Does the workpiece require further processing after welding?

1. Post-weld Heat Treatment:

● If the weld requires solution treatment and artificial aging (e.g., T6 temper), ER4043 should be selected. ER5356 significantly loses strength after high-temperature heat treatment.

② Post-weld Anodizing:

● As mentioned above, careful wire selection is required to match the color. ER5356 is generally a better choice than ER4043.

③ Brazing:

● This is a different joining process that requires specialized aluminum brazing filler metals (typically with a higher silicon content and a lower melting point), which are different from welding filler metals.

Summary and Quick Reference

Final Recommendation: When making your selection, always consult authoritative filler metal selection charts and combine them with specific project requirements (e.g., codes, standards, and specifications) to make your final decision. For uncertain applications, performing a welding procedure qualification test is a best practice to verify the suitability of the filler metal.