Ferritic Stainless Steel Welding

Ferritic stainless steel welding is a type of stainless steel with chromium as the primary alloying element (typically between 10.5% and 30%), a low carbon content, and a predominantly ferrite structure in service. Its performance characteristics lie between those of martensitic and austenitic stainless steels.Ferritic Stainless Steel Welding

Core Characteristics:

1. Microstructure: Its name derives from its stable microstructure—ferrite (body-centered cubic). This structure persists from high to low temperatures and cannot be strengthened by heat treatment (such as quenching). This is its fundamental difference from martensitic stainless steel.

2. Chemical Composition:

● Chromium Content: High chromium content, typically between 10.5% and 30%, is its core element, providing excellent corrosion resistance.

● Carbon Content: Very low (typically <0.08%) to prevent the formation of excessive chromium carbides and thus maintain corrosion resistance.

● Other Elements: It contains virtually no nickel (a key difference from austenitic stainless steel), resulting in a lower cost. Modern high-performance ferritic stainless steels often have molybdenum (Mo) added to improve pitting corrosion resistance, and titanium (Ti) or niobium (Nb) added to stabilize carbon and nitrogen (“stabilization”) to prevent intergranular corrosion.

Key Performance Characteristics:

Advantages:

1. Good corrosion resistance: Ferritic stainless steels offer superior resistance to chloride stress corrosion cracking (SCC), particularly compared to austenitic stainless steels. This is one of their most significant advantages. They also offer good resistance to uniform corrosion in some mildly corrosive environments.

2. Magnetism: All ferritic stainless steels are magnetic, which can be used to quickly distinguish them from non-magnetic austenitic stainless steels.

3. Moderate strength: Ferritic stainless steels offer higher strength than austenitic stainless steels, but lower than heat-strengthened martensitic stainless steels.

4. Low and stable cost: Ferritic stainless steels contain little or no nickel, making them less susceptible to nickel price fluctuations and generally cheaper than austenitic stainless steels.

5. High thermal conductivity and low thermal expansion coefficient: Its thermal conductivity is approximately 30-40% better than that of austenitic stainless steel, and its thermal expansion coefficient is closer to that of carbon steel. This makes it more resistant to thermal fatigue under thermal cycling conditions (such as heat exchangers) and results in relatively less welding distortion.

Disadvantages:

1. Sensitivity to intergranular corrosion: During welding or at high temperatures (450-850°C), chromium carbides (Cr₂₃C₆) of medium-chromium steel (such as 430) precipitate along grain boundaries, leading to chromium depletion near the grain boundaries and causing intergranular corrosion. This can be addressed through “stabilization” treatment (adding Ti/Nb) or using ultra-low carbon steel (such as 439).

2. Poor room-temperature toughness and a brittle transition:

● Brittleness at 475°C: After prolonged heating in the 375-525°C temperature range, chromium-rich phases precipitate, causing a sharp decrease in toughness and an increase in hardness.

● High-temperature brittleness (sigma phase embrittlement): In high-chromium steels, prolonged heating at 550-800°C forms a hard and brittle intermetallic compound, the sigma phase, making the material brittle.

● Low-temperature brittleness: Toughness decreases with decreasing temperature, with a distinct ductile-brittle transition temperature. Therefore, use in low-temperature environments is generally not recommended.

3. Fair weldability: Welding thermal cycling may cause grain coarsening and embrittlement in the heat-affected zone (HAZ) (sigma phase or 475°C brittleness), reducing toughness and corrosion resistance.

Common grades, classifications, and applications:

Ferritic stainless steels also belong to the 400 series and can be divided into the following categories based on chromium content and properties:

1. Low-chromium steel (Cr ≈ 11%-14%)

● 409 (UNS S40900): The cheapest ferritic stainless steel, titanium-stabilized. Corrosion resistance is fair, but superior to carbon steel.

▶ Applications: Primarily used in automotive exhaust systems (mufflers, tailpipes), containers, and heat exchanger piping.

2. Medium Chromium Steel (Cr ≈ 16%-18%)

●430 (1.4016, UNS S43000): The most classic and commonly used ferritic stainless steel, also known as “stainless steel.” It has good atmospheric corrosion resistance, but poor weldability and intergranular corrosion resistance.

▶Applications: Architectural decoration, household appliance components (washing machine drums, microwave oven housings), nitric acid production equipment, and tableware.

●439 (UNS S43035): A modified version of 430, stabilized by the addition of titanium (Ti), significantly improving weldability and intergranular corrosion resistance.

▶Applications: Automotive exhaust systems (head pipes, catalytic converter housings), sinks, and water heater tanks.

3. High Chromium-Molybdenum Steel (Cr ≈ 18%-30%, often containing Mo)

●444 (1.4521, UNS S44400): Contains 18% Cr and 2% Mo, stabilized with Nb and Ti. Its pitting and crevice corrosion resistance is comparable to or even better than that of 304, and it also has excellent resistance to stress corrosion cracking.

▶Applications: Hot water storage tanks, solar systems, heat exchangers, water treatment equipment, and the food industry.

●446 (UNS S44600): High chromium (25%), it offers excellent resistance to high-temperature oxidation and sulfidation, but is brittle at room temperature.

▶Applications: High-temperature, heat-resistant components such as burners and annealing furnace hoods.

Heat Treatment and Welding:

●Heat Treatment: Strengthening is not possible through heat treatment. The primary heat treatment is annealing (approximately 780-850°C), which relieves processing stresses, softens the material, and homogenizes the structure, followed by rapid cooling through the 475°C brittle zone.

●Welding:

▶The primary concern is grain growth and embrittlement in the heat-affected zone.

▶Use low heat input welding methods (such as TIG welding) and accelerated cooling rates.

▶For unstabilized steels, post-weld annealing is often required to restore corrosion resistance and toughness.

▶It is important to select the right welding consumables (such as homogeneous ferritic welding consumables or heterogeneous austenitic welding consumables such as 309L).

When welding ferritic stainless steel, choosing the right welding consumables and combining them with the appropriate process are crucial. Below, I’ll review the types of ferritic stainless steel welding consumables, key selection criteria, common problems, and solutions, and provide some selection recommendations.

Welding consumable types and selection:

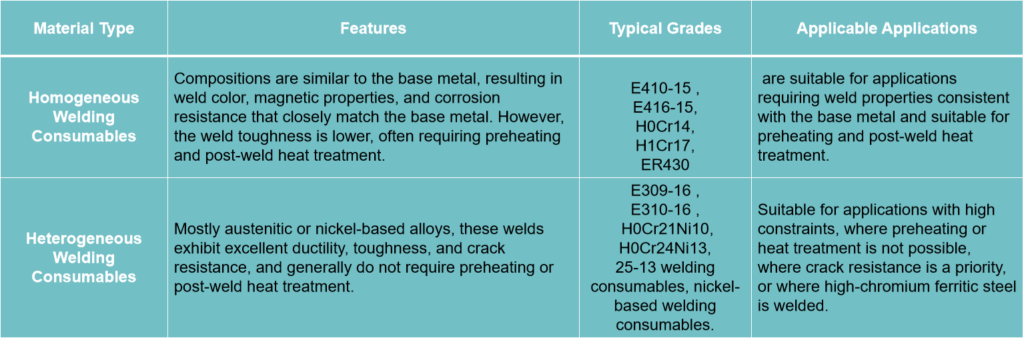

Ferritic stainless steel welding consumables are primarily divided into two categories: homogeneous and heterogeneous. The table below provides a quick overview of their characteristics and typical grades:

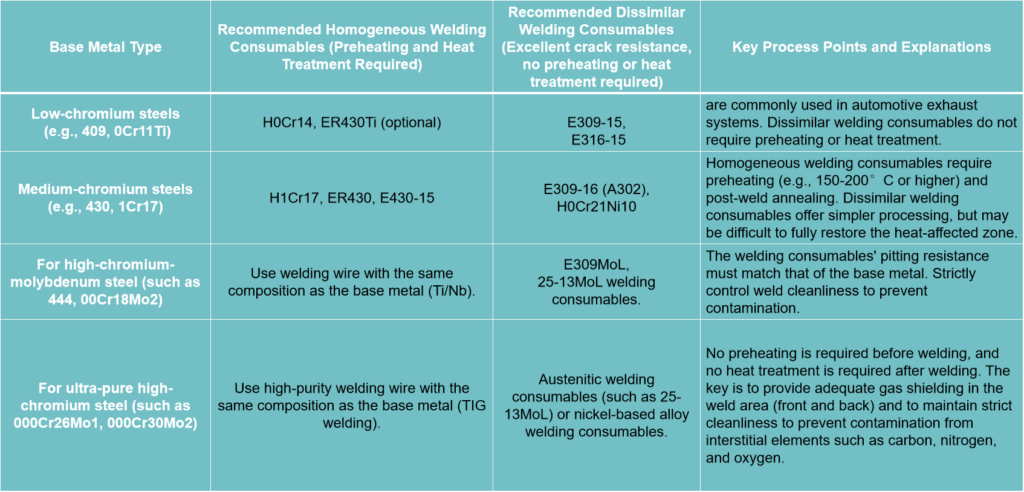

Selection strategy:

● Pursue consistent performance: If preheating and post-weld heat treatment can be strictly implemented, homogeneous welding consumables can be selected.

● Prioritize welding success rate: If the structure is complex, preheating or heat treatment is not possible, or if crack resistance and ductility are of primary concern, heterogeneous austenitic or nickel-based welding consumables should be selected.

Major Welding Issues and Countermeasures:

When welding ferritic stainless steel, special attention should be paid to the following issues:

● Intergranular Corrosion: During welding, chromium carbides (Cr₂₃C₆) are prone to precipitating at grain boundaries in the 450-850°C range, resulting in chromium depletion near the grain boundaries and causing intergranular corrosion.

▶ Countermeasure: Select base metal and welding consumables with ultra-low carbon content or those containing stabilizing elements (Ti, Nb). For ordinary ferritic stainless steel, post-weld heat treatment (annealing at 750-800°C followed by rapid cooling) facilitates the redispersion of chromium and restores corrosion resistance.

● Welding Embrittlement: Mainly includes:

▶ Coarse Grain Size: Ferritic steel exhibits no phase transformation, resulting in increased grain size in the heat-affected zone after welding, leading to a decrease in toughness. Using low heat input, narrow weld beads, and fast welding can help alleviate this problem.

▶ 475°C Brittleness: Prolonged heating in the 375-525°C range causes the precipitation of chromium-rich phases, leading to a sharp decrease in toughness. Avoid prolonged exposure to this temperature range during welding, and control the interpass temperature.

▶σ-phase embrittlement: In high-chromium steel, prolonged heating at 550-800°C can form a hard and brittle intermetallic compound called the σ-phase, making the material brittle. Rapid cooling after post-weld heat treatment can help overcome this critical temperature range.

●Weld cracking: Although the tendency to cold cracking is lower than that of martensitic stainless steel, it still requires attention.

▶Countermeasures: Preheat (common ferritic steels are typically preheated to 100-200°C or higher), use low-hydrogen welding consumables and processes, and reduce welding stress.

Key points of welding technology:

Successful welding requires appropriate process coordination:

●Pre-weld preparation: Thoroughly clean the groove and both sides of the groove from oil, water, rust, and other contaminants to reduce hydrogen sources and contamination.

●Preheating and interpass temperature: For common ferritic stainless steels, preheating is generally required (e.g., 100-200°C or higher, depending on composition and thickness), and the interpass temperature should be controlled to avoid excessively high temperatures.

● Welding Methods:

▶ Gas Tungsten Arc Welding (TIG/GTAW): Commonly used for root welding of thin plates, pipes, and critical components, offering high quality.

▶ Metal Shielded Metal Arc Welding (SMAW): Flexible, convenient, and widely applicable.

▶ Gas Metal Inert Gas Welding (MIG/GMAW): Highly efficient and can use argon-rich mixed gas shielding.

▶ For both methods, low heat input and high welding speeds are recommended.

● Post-weld Heat Treatment: For ordinary ferritic stainless steels, post-weld annealing at 750-800°C followed by rapid cooling can improve corrosion resistance and ductility and prevent embrittlement. Ultra-pure ferritic stainless steels generally do not require post-weld heat treatment.

Examples of Common Ferritic Stainless Steel Welding Consumables:

Summary and Reminders:

When welding ferritic stainless steel, the key is to prevent embrittlement and intergranular corrosion. Preheating and post-weld heat treatment should be determined based on the specific conditions. Remember the following key points:

● Careful material selection: Choose homogeneous or heterogeneous welding consumables based on your primary requirements for weld performance (corrosion resistance, toughness, color matching), base material type (normal or ultrapure), and process conditions (whether preheating/heat treatment is possible).

● Strict process control: Parameters such as preheat temperature, interpass temperature, heat input, welding speed, and post-weld heat treatment are crucial.

● Maintain cleanliness: From consumable storage and drying to groove cleaning, every step must be meticulous, especially for ultrapure ferritic stainless steels.

● Complex or critical components: Before proceeding with production welding, performing a welding procedure qualification (WPS/PQR) is essential to ensure quality and reduce risk.