Nuclear industry welding materials (2)

This is a highly specialized and important question. The nuclear industry places extremely stringent demands on welding materials, as welding quality is directly linked to the safety, reliability, and lifespan of nuclear facilities. Welding materials used in the nuclear industry must not only possess the excellent mechanical and process properties required in conventional industries, but also possess the following specialized properties:

● Excellent radiation resistance: Inside the reactor core, materials are subjected to intense neutron radiation, which can cause embrittlement of welded joints.

● Excellent corrosion resistance: They must be able to withstand long-term corrosion from coolants such as high-temperature, high-pressure water, liquid metals (such as sodium, lead, and bismuth), and molten salts.

● Extremely low thermal cracking susceptibility: They prevent cracking during welding and service.

● Extremely high purity: The content of impurities such as sulfur and phosphorus is strictly limited to ensure toughness and crack resistance.

● Good long-term thermal stability: For long-term service at high temperatures, the structural properties must be stable and resistant to aging.

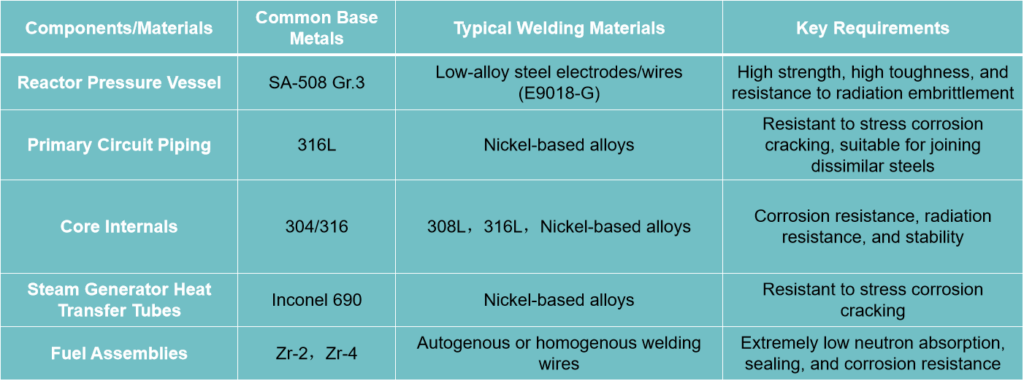

The following is a classification and examples of commonly used welding materials for different components and environments in the nuclear industry:

I: Nuclear-grade stainless steel welding materials: Primarily used in the manufacture of reactor pressure vessel linings, internal components, main piping, surge tubes, pressurizers, and various auxiliary system piping.

① Austenitic stainless steels: such as 308L, 309L, and 316L.

● Applications: Primarily used for welding austenitic stainless steel components such as 304, 304L, 316, and 316L.

● Features: The “L” designation indicates ultra-low carbon, effectively preventing intergranular corrosion caused by chromium carbide precipitation during welding, a fundamental requirement for nuclear-grade welding materials.

● Typical grades: ER308L and ER316L welding wire; E308L-16 and E316L-16 welding rods.

② Martensitic/precipitation-hardening stainless steels: such as 410 and 17-4PH.

● Applications: Primarily used in the manufacture of components requiring high strength, such as main pump shafts and valve stems.

● Welding materials: Requires matching composition and rigorous heat treatment.

II: Nickel-based alloy welding materials: These are among the most critical welding materials in the nuclear industry, especially for pressurized water reactor (PWR) primary systems. They offer excellent resistance to stress corrosion cracking (SCC), thermal strength, and structural stability.

① Main types: ENiCrFe-3 and ENiCrFe-7 (ERNiCrFe-7A).

● Welding wires: ERNiCrFe-7A and ERNiCr-3 are used for automatic welding methods such as TIG and MIG.

● Welding rods: ENiCrFe-7 and ENiCrFe-3 are used for manual metal arc welding (SMAW).

● Applications:

▷ Dissimilar metal welding: This is its most important application, such as joining low-alloy steel pressure vessels and stainless steel main piping. Nickel-based alloys as filler metals can effectively alleviate stress caused by the difference in thermal expansion coefficients between the two, significantly reducing the risk of cracking.

▷ Welding of reactor internal components: Components requiring high radiation resistance.

▷ Steam generator heat transfer tubes.

III: Low-alloy, high-strength steel welding consumables: Primarily used for welding pressure-bearing components such as the cylinder of a nuclear reactor pressure vessel (RPV). Pressure vessels are typically made of low-alloy, high-strength steels such as SA-508 Gr.3 Cl.1 (US designation) or 18MND5 (French designation).

● Type: Typically a low-hydrogen electrode and flux-wire combination.

● Features: The composition matches the base metal, but the impurity and hydrogen content are strictly controlled. Strict stress relief heat treatment (SRHT) is required after welding.

● Typical grades:

▷ Welding rods: Comply with AWS E9018-G (e.g., US/Chinese standards).

▷ Submerged arc welding: Uses a specific composition of welding wire (e.g., S3NiMo) with a neutral or basic sintered flux.

IV: Zirconium alloy welding consumables: Specifically used in the manufacture of fuel assemblies, such as the seal welding of fuel element end plugs to the cladding tube. Zirconium alloys (such as Zr-2 and Zr-4) have a very small thermal neutron absorption cross section and exhibit excellent resistance to high-temperature aqueous corrosion.

● Welding Method: Vacuum electron beam welding (EBW) or inert gas welding (TIG/GTAW) is almost exclusively used.

● Features: Requires protection under extremely high-purity inert gas to prevent oxidation. This process is typically autogenous, meaning the weld is formed by directly melting the base metal without the use of additional filler material. Sometimes, a zirconium alloy wire with the same composition as the base metal is used as filler metal.

Overview of Welding Methods:

The welding method is closely related to the welding materials. Nuclear facilities primarily utilize highly automated, reliable, and high-quality methods:

● Tungsten Inert Gas Welding (TIG/GTAW): The most widely used and highest-quality method, used for root passes and critical welds.

● Submerged Arc Welding (SAW): Used for welding thick-walled components, offering high efficiency and consistent quality.

● Manual Metal Arc Welding (SMAW): Used for installation, maintenance, and other applications where automated welding is inconvenient.

●Electron beam welding (EBW): Used for precision components, such as fuel rod seal welding.

●Laser beam welding (LBW): An emerging technology, gradually being applied in certain specific areas.

Summary and Core Features

Most importantly, all Nuclear industry welding materials must comply with extremely stringent nuclear-grade standards and specifications (e.g., ASME Section 11.1). III, RCC-M, etc.) and undergo comprehensive qualification certification, including process assessment and welder examination, to ensure their performance is foolproof. The procurement, storage, use and traceability of these materials are subject to very strict management procedures.