Stainless steel submerged arc welding wire

Stainless steel SAW is a submerged arc welding material specifically designed for welding stainless steel. It works in conjunction with a matching flux to obtain welds with specific corrosion resistance and mechanical properties.Stainless steel submerged arc welding wire

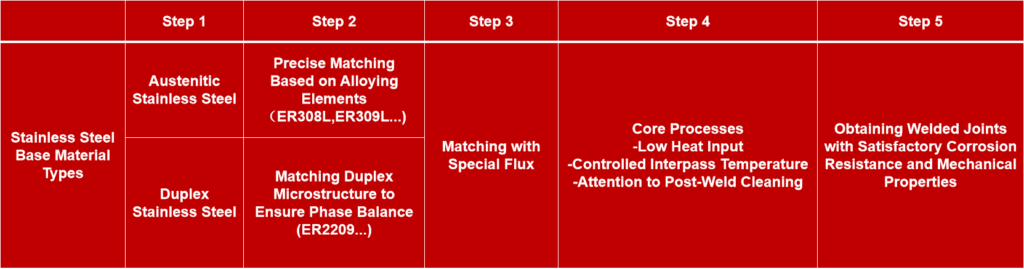

一. Stainless Steel Submerged Arc Welding Wire Selection Guide

The core principle for selecting stainless steel SAW is “equal composition matching,” meaning the chemical composition of the welding wire must be similar to that of the base metal to ensure that the corrosion resistance of the weld is consistent with that of the base metal. The selection logic can be summarized as follows:

二. Common Types and Models of Stainless Steel Submerged Arc Welding Wire

Based on the selection path shown in the diagram above, the following are some common types and models of stainless steel SAW (mainly following the AWS A5.9 standard):

❶ Austenitic Stainless Steel Submerged Arc Welding Wire

This is the most commonly used type, used for welding corresponding austenitic stainless steels.

⑴ EQ308L: Corresponds to the national standard H00Cr21Ni10. Used for welding 304L stainless steel, ultra-low carbon, with strong resistance to intergranular corrosion.

(2) EQ309L: Used for welding dissimilar metals (such as carbon steel and stainless steel) or for surfacing transition layers.

(3) EQ316L: Corresponds to national standard H00Cr19Ni12Mo2. Used for welding 316L stainless steel, containing molybdenum, offering better resistance to pitting corrosion and creep.

(4) EQ347: Corresponds to national standard H00Cr20Ni10Nb. Used for welding 321, 347, and other stainless steels containing stabilizing elements (Nb), further improving resistance to intergranular corrosion.

❷ Duplex Stainless Steel Submerged Arc Welding Wire

Used for welding duplex stainless steel, its weld metal has a dual-phase structure of austenitic and ferritic components, combining high strength and good resistance to stress corrosion.

(1) EQ2209: Used for welding 2205 (S31803/S32205) duplex stainless steel. The ferrite content of the weld metal is typically controlled between 30% and 55%.

Please note: The above models are welding wire models and must be used in conjunction with flux in actual applications.

三. Core Points of Welding Process

When welding stainless steel, the process must be strictly controlled to prevent a decline in weld performance. The core points are as follows:

❶ Flux Selection and Management

⑴ Special Flux: Stainless steel-specific flux (usually sintered type) must be used. Ordinary carbon steel flux will contaminate the weld, leading to alloy element loss and a severe decrease in corrosion resistance.

⑵ Basicity Matching: Select the appropriate flux basicity based on the requirements for weld metal toughness and corrosion resistance.

⑶ Moisture Prevention and Recycling: Flux must be dried according to regulations before use. When reused, it must be sieved and mixed with new flux in the specified proportion.

❷ Strict Control of Heat Input

Use lower heat input and faster welding speed.

⑴ Excessive heat input will lead to:

● Austenitic Stainless Steel: Coarse grains in the heat-affected zone of the weld, decreased corrosion resistance, and susceptibility to knife-like corrosion.

● Duplex Stainless Steel: Increased ferrite content disrupts phase balance, worsening toughness and corrosion resistance.

❸ Controlling Interpass Temperature

⑴ It is recommended to control the interpass temperature below 150℃. For thick-walled weldments, forced cooling measures (such as back-side air blowing) may be necessary, but care must be taken to avoid hardening cracks.

❹ Pre-weld Cleaning and Post-weld Treatment

⑴ Pre-weld Cleaning: Oil, moisture, and impurities must be thoroughly removed from the bevel and both sides. Specialized stainless steel cleaning tools are recommended.

⑵ Post-weld Cleaning: After welding, weld slag and spatter in the weld and adjacent areas must be thoroughly removed. These residues can damage the passivation film on the stainless steel surface, leading to pitting corrosion. Mechanical (stainless steel wire brush) or chemical (acid pickling and passivation) methods are typically used.

Hopefully, this systematic introduction will help you gain a comprehensive understanding of stainless steel submerged arc welding wire. If you can provide specific base metal models (such as 304L, 316L, 2205, etc.) and working conditions, I can provide you with more specific selection and process recommendations.