Welding heat input

Understanding the differences in heat input sensitivity between flux-cored and solid welding wires, and why strict heat input control is essential for high-strength steel welding, is fundamental to ensuring the welding quality of critical structures.

一. Flux-cored Wire vs. Solid Welding Wire: Sensitivity to Heat Input

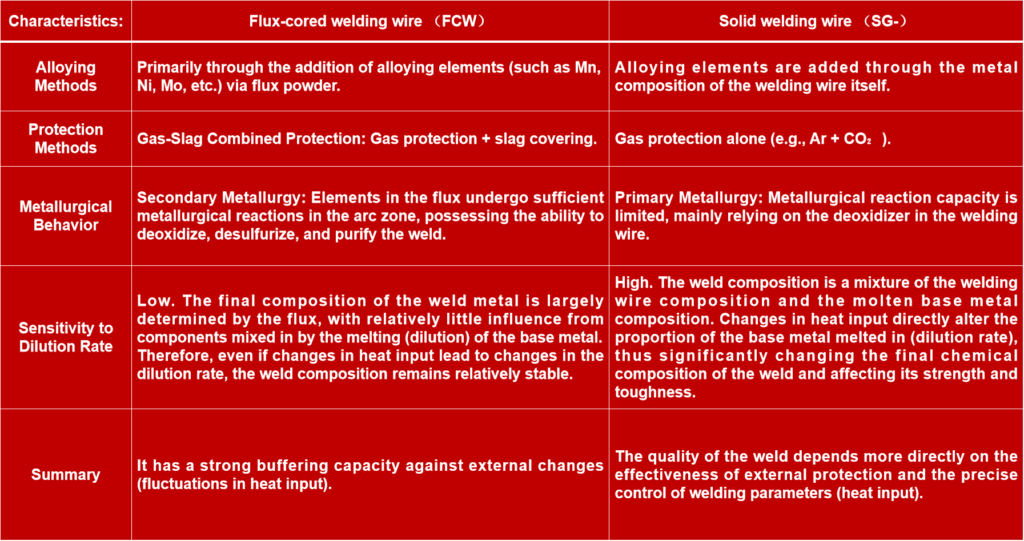

In general, flux-cored welding wires are less sensitive to fluctuations in heat input, or have a higher tolerance, while solid welding wires have stricter requirements for heat input control. The fundamental reason behind this lies in the essential differences in their metallurgical processes and alloying methods.

Conclusion: In on-site construction where strict heat input control is required but parameter fluctuations are difficult to completely avoid (such as ship hulls and building construction), the use of flux-cored welding wire often yields more stable and predictable weld performance.

二. Why is Strict Heat Input Control Necessary for High-Strength Steel Welding?

In welding high-strength steel (especially quenched and tempered steel with a yield strength ≥ 690 MPa), strict heat input control is not just a suggestion, but an ironclad rule. The reason lies in the fact that the superior properties of high-strength steel (high strength, high toughness) do not stem from simple alloying, but from its specific microstructure, which is achieved through rolling, controlled cooling, and, most importantly, tempering heat treatment.

The welding thermal cycle is essentially a “destruction and reconstruction” of the original heat-treated state of the tempered steel.

❶ The emergence of the heat-affected zone (HAZ): The base metal region adjacent to the weld is heated to different peak temperatures during welding and then cooled at different rates. This region is the HAZ, the weakest point in the welded joint.

❷ Damage to the original microstructure:

● The base metal microstructure of tempered steel is tempered sorbite, which combines strength and toughness.

● During the welding thermal cycle, the region near the fusion line is heated to temperatures far above the phase transformation point (Ac3), and the original tempered sorbite transforms into coarse austenite.

● Upon subsequent cooling, this austenite transforms into coarse, brittle martensite or upper bainite, etc.

The magnitude of the heat input directly determines the severity of this “damage.”

三. Specific Negative Impacts of Excessive Heat Input on Weld Microstructure and Properties

Heat Input = (Voltage × Current × 60) / Welding Speed. Excessive heat input means high welding energy, slow heating, and slow cooling.

❶ Impact on the Heat-Affected Zone (HAZ)

⑴ Severe Grain Coarsening: Long high-temperature residence time leads to rapid austenite grain growth. Upon cooling, it transforms into coarse martensite or upper bainite. This results in a sharp decrease in the toughness (impact energy) of the HAZ, an increase in the brittle transition temperature, and a decrease in the joint’s resistance to brittle fracture.

⑵ Formation of Softening and Embrittling Zones:

● Softening Zone: In the region between Ac1 and Ac3 at the peak temperature, the original tempered sorbite undergoes only partial phase transformation or tempering, leading to carbide aggregation and growth, forming a soft, ductile zone with significantly lower strength and hardness than the base metal. This is a potential fracture source under load.

● Embrittlement Zone: In the slightly more distant low-temperature tempering zone (peak temperature approximately between 400°C and Ac1), the microstructure may transform into lower bainite or temper brittle microstructure with poor toughness.

❷ Effects on Weld Metal

⑴ Coarse Weld Grains: Also coarse due to long high-temperature residence time, leading to decreased strength and toughness.

⑵ Alloy Element Loss: Especially for solid welding wire, excessive heat input increases the oxidation loss of alloying elements (such as Mn, Si, etc.), altering the weld composition and resulting in insufficient strength.

⑶ Increased Tendency to Solidification Cracks: Coarse columnar grain structures more easily promote the aggregation of low-melting-point eutectics at grain boundaries, increasing the risk of hot cracking.

❸ Overall Structural Problems

⑴ High Welding Stress and Deformation: High heat input leads to greater thermal expansion and contraction, resulting in higher residual welding stress and more severe structural deformation.

(2) Decreased resistance to cold cracking: Although a slow cooling rate facilitates hydrogen escape and reduces the tendency to cold crack, this benefit is often offset by the deterioration in toughness caused by grain coarsening in modern low-hydrogen welding materials. The coarse microstructure itself is more sensitive to hydrogen-induced cracking.

四: Summary and Analogy

You can imagine the tempered microstructure of high-strength steel as a “carefully constructed Lego castle,” strong yet flexible.

● Welding heat input is like a localized “earthquake” on the castle.

● Appropriate heat input is equivalent to a gentle tremor; after local reconstruction, the structure remains stable.

● Excessive heat input is equivalent to a violent earthquake, causing the castle’s foundation (grains) to become coarse and loose, and resulting in weak sandy areas (softening zones) and fragile ice blocks (embrittlement zones) in certain areas (HAZ), thus destroying the strength and toughness of the entire structure (welded joint).

Therefore, in high-strength steel welding, a “low heat input, multi-pass welding” process is commonly used. By effectively “tempering” the HAZ of the previous weld pass through subsequent weld passes, the grains can be refined and the microstructure improved, thereby obtaining a welded joint with excellent overall performance.