Special welding materials ,ERNiCrCoMo-1 is a high-performance nickel-chromium-cobalt-molybdenum alloy welding consumable with excellent high-temperature strength, oxidation resistance, and corrosion resistance.Special welding materials ,ERNiCrCoMo-1

📌一. Basic Overview

ERNiCrCoMo-1 is a nickel-based high-temperature alloy welding consumable that complies with AWS A5.14 ERNiCrCoMo-1 (welding wire) and AWS A5.11 ENiCrCoMo-1 (welding rod). Its corresponding high-performance alloy is INCONEL 617. It is specifically designed for welding high-temperature and corrosion-resistant nickel-chromium-cobalt-molybdenum alloys, and is particularly suitable for welding and repairing critical components in high-temperature and high-pressure environments.

🧪 二. Chemical Composition and Performance Characteristics

2.1. Core Chemical Composition:

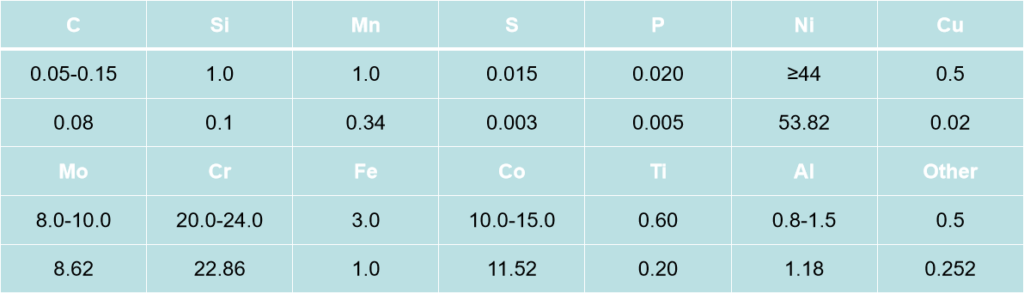

The typical chemical composition (mass fraction) of ERNiCrCoMo-1 is shown in the following table:

Note: The specific content ranges in different standards (e.g., AWS and GB) may vary slightly; the values listed above are typical values. The addition of cobalt (Co) and molybdenum (Mo) significantly improves its high-temperature strength and creep resistance.

2.2: Material Properties:

Due to its unique chemical composition, ERNiCrCoMo-1 exhibits the following exceptional properties:

a: Excellent High-Temperature Performance: Maintains high strength, high creep resistance, and excellent resistance to oxidation and scaling in the high-temperature range of 650°C to 1150°C.

b: Excellent Corrosion Resistance: Resists a wide range of corrosive media, including acids, alkalis, seawater, and high-temperature sulfide and chloride environments, with excellent resistance to pitting and crevice corrosion.

c: Excellent Mechanical Properties: The deposited metal exhibits high strength and good ductility. Typical room-temperature mechanical properties are as follows:

· Tensile strength (Rm): ≥ 620 MPa (AWS requirement), typically 770-787 MPa

· Yield strength (Rp0.2): ≥ 400 MPa, typically 527-610 MPa

· Elongation after fracture (A): ≥ 22%, typically 28-38.5%

d: Low hot crack susceptibility: Strict control of carbon content and impurity elements (such as S and P) reduces the risk of hot cracking during welding.

e: Excellent weldability: Suitable for a variety of welding methods, with excellent processability and capable of welding in all positions.

Due to its outstanding performance, ERNiCrCoMo-1 welding consumables are widely used in the welding and repair of the following high-end equipment manufacturing and key components:

a: Aerospace Industry: Aircraft engine components (such as combustion chambers and transition pieces), gas turbine blades, and rocket engine components.

b: Power Generation Equipment: Gas turbine components, ultra-supercritical power plant boilers (such as superheater and reheater piping), nuclear reactor pressure vessel seal surface cladding, steam generator heat transfer tube repair, and high-temperature furnace components.

c: Fossil and Nuclear Energy: Heat treatment furnace components, catalytic converters, and ammonia reformers.

d: Petrochemical Equipment: Heat exchangers, reactors, piping systems, chimney linings resistant to sulfuric acid dew point corrosion, and other equipment exposed to corrosive media.

e: Marine Engineering: Key components of offshore platforms, ship engine exhaust systems, and other equipment resistant to seawater corrosion.

f: Other: Suitable for welding nickel-based or iron-nickel-based high-temperature alloys such as INCONEL 617 (UNS N06617) and INCOLOY 800H/825 to themselves, as well as dissimilar metal welding to stainless steel and carbon steel.

The successful application of ERNiCrCoMo-1 requires special attention to the following process requirements:

1. Welding Method

1.1: Primarily used for inert gas shielded welding, including:

a: TIG welding (GTAW): Suitable for thin plate and precision welding, requiring high-purity argon (≥99.99%) shielding.

b: MIG welding (GMAW): For efficient welding of medium and thick plates, an argon + helium (Ar+He) gas mixture is recommended to improve arc stability and penetration.

c: Also commonly used in manual metal arc welding (SMAW), using ENiCrCoMo-1 electrodes.

2. Process Parameter Control

2.1: Current and Polarity:

a: TIG/MIG welding: Typically uses direct current (DCEN/DCEP) polarity.

b: Metal arc welding: Uses direct current (DC+) polarity. c: The current range should be adjusted according to the consumable diameter (for example, for a 1.2mm wire diameter, the current is approximately 160-280A).

2.2: Preheating and Interpass Temperature:

a: The recommended preheat temperature for the base metal is 100°C to 150°C.

b: The interpass temperature must be strictly controlled below 150°C to avoid overheating and grain coarsening.

c: Heat Input Control: Low heat input and low interpass temperatures are recommended, along with narrow, multi-pass welding techniques to avoid intergranular segregation.

2.3: Shielding Gas:

a: TIG welding: Pure argon, flow rate 12-18 L/min.

b: MIG welding: An argon-helium mixture (e.g., 75% Ar + 25% He) is recommended, flow rate 20-25 L/min to enhance penetration and wettability.

3. Pre- and Post-Weld Treatment

a: Pre-weld cleaning: This is crucial. Thoroughly remove oil, moisture, and oxides from the base metal groove and surrounding areas, as well as from the welding wire surface (acetone cleaning and stainless steel brush polishing are recommended) to prevent porosity and cracks.

b: Welding material preparation: Welding rods are typically baked at 300°C-350°C for one hour before use and should be used immediately to prevent moisture absorption.

c: Post-weld heat treatment: Post-weld solution or aging treatment is generally not mandatory to avoid damaging the weld structure. However, for certain special requirements or complex structures, this may be considered based on actual conditions.

d: Surface cleaning: Oxidation discoloration can be removed after welding. Using a stainless steel brush or pickling (such as a 10% nitric acid + 2% hydrofluoric acid solution) is recommended.

a: Porosity: Nickel-based alloys have poor molten pool fluidity, which can easily trap gas. This can be addressed by increasing the shielding gas purity, increasing the shielding gas flow rate, and reducing the welding speed.

b: Lack of fusion: Adjust the welding torch angle (recommended 10°-15° back tilt) and increase the arc voltage appropriately.

c: Stress corrosion cracking: For harsh environments, consider post-weld peening or shot peening to relieve residual stress.

d: Hot crack susceptibility: Although the alloy itself has low hot crack susceptibility, strict control of impurity elements (S, P) and weld cleanliness are still required.

e: Storage requirements: Welding materials should be stored in a dry environment (humidity <30%). Vacuum-packed materials must be protected from moisture absorption after opening.

With the development of cutting-edge technologies such as ultra-supercritical power generation, fourth-generation nuclear reactors, and aerospace, the demand for welding materials capable of operating in more extreme environments is increasing. Future development of ERNiCrCoMo-1 may focus on:

a: Material modification: For example, adding nano-oxides (such as Y₂O₃) to refine grain size and further enhance performance.

b: Intelligent welding: Incorporating AI algorithms to optimize welding process parameters and improve weld quality and consistency. c: Additive Manufacturing (3D Printing): Develop specialized welding wire specifications suitable for additive manufacturing, enabling the direct fabrication of complex structural components.

Special welding materials ,ERNiCrCoMo-1 is a high-performance nickel-chromium-cobalt-molybdenum alloy welding consumable. Its exceptional high-temperature strength, excellent oxidation and corrosion resistance make it a key material for welding high-temperature alloys such as INCONEL 617, as well as for the manufacturing and repair of high-end equipment in the aerospace, energy, and chemical industries. Its successful application relies on rigorous pre-weld cleaning, precise control of process parameters (particularly heat input and interpass temperature), and meticulous attention to welding details.Special welding materials ,ERNiCrCoMo-1