308 series stainless steel

ER308L is an ultra-low carbon austenitic stainless steel welding wire primarily used for welding 304L (022Cr19Ni10) stainless steel. It offers excellent intergranular corrosion resistance and excellent weldability.308 series stainless steel

https://www.akweld.com/wp-content/uploads/2025/08/ER308L.pdf

① Main Applications: Widely used in applications requiring high corrosion resistance, such as petrochemical equipment, pressure vessels, food processing machinery, medical devices, power plant construction, automotive exhaust systems, and marine engineering.

② Welding Performance: Features stable arc, minimal spatter, and aesthetically pleasing weld bead formation, making it suitable for welding in all positions (horizontal, horizontal, vertical, and overhead).

③ Core Advantages: Its “ultra-low carbon” (C ≤ 0.03%) significantly reduces the risk of carbide precipitation in the weld metal, providing excellent intergranular corrosion resistance. It is particularly suitable for welding 304L stainless steel and structural components operating in corrosive environments.

Welding methods and parameters directly affect the final weld quality. The following are common reference specifications:

① Reference Current (using a 1.2mm diameter wire as an example):

② Key Operation Points:

ER308LSi is an ultra-low-carbon, silicon-containing, austenitic stainless steel gas shielded welding wire widely used for its excellent welding processability and weld quality.

🔬Chemical Composition and Mechanical Properties

https://www.akweld.com/wp-content/uploads/2025/08/ER308LSi.pdf

⚙️ Key Welding Operation Guidelines

To achieve optimal welding results, the following points should be observed during operation:

① Pre-weld Cleaning: Before welding, the weld groove and the welding wire surface must be thoroughly cleaned of impurities such as oil, rust, and moisture. During cleaning, it is best to polish the groove surface and surrounding area to a metallic luster. This is a key step in preventing weld porosity and cracks.

② Shielding Gas:

▶ MIG Welding: A mixture of Ar + (1-5)% CO₂ or Ar + (1-3)% O₂ is recommended. The gas flow rate is recommended to be controlled at 20-25 L/min.

▶ TIG Welding: Pure argon (Ar) with a purity of at least 99.99% should be used as the shielding gas.

③ Process Parameters:

▶ Stickout Length: Generally recommended to be maintained at 15-25 mm.

▶ Reference Current: Taking a 1.2 mm diameter wire as an example, the current range for flat and horizontal welding is approximately 140-220 A, and for vertical and overhead welding is approximately 140-200 A. The current range for a 0.8 mm diameter wire is approximately 70-150 A, and for a 1.0 mm diameter wire is approximately 100-200 A.

④ Wind Protection: When welding outdoors, if the wind speed exceeds 1.5 m/s, effective wind protection measures must be implemented to prevent the shielding gas from being blown away and causing air holes.

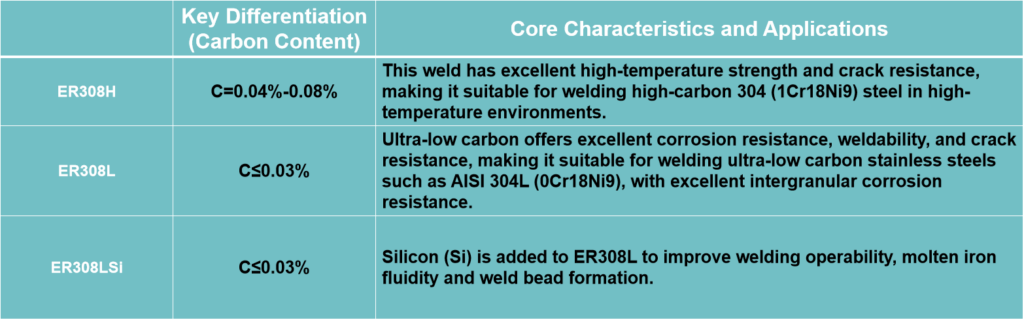

ER308H is an austenitic stainless steel welding wire. Its key feature is its high carbon content, making it particularly suitable for applications requiring high-temperature strength. The table below compares it with the previously mentioned ER308L and ER308LSi to more clearly illustrate the differences.

🔬 Comparison of Three ER308 Series Welding Wire Cores

⚙️ ER308H Welding and Application Key Points

① Main Applications: Primarily used for welding 18Cr-8Ni stainless steel (such as 12Cr18Ni9/SUS 302, 06Cr19Ni10/SUS 304). These materials are commonly used in the petrochemical industry, pressure vessels, food processing machinery, medical equipment, and other fields.

② Welding Performance: Stable arc, beautiful weld bead, strong crack resistance, and capable of welding in all positions.

③ Operating Recommendations:

▶ Shielding Gas: For MIG welding, a mixture of Ar + (1-3)% O₂ is recommended, while for TIG welding, pure argon (Ar) is recommended.

▶ Pre-weld Cleaning: Rust, oil, moisture, and other impurities must be removed from the weldment.

💎 Summary and Selection Recommendations

The choice of welding wire depends primarily on your specific requirements for corrosion resistance and high-temperature strength:

① If the workpiece needs to operate in a high-temperature environment and withstand loads, ER308H is the preferred choice.

② If the working environment contains corrosive media (such as chemical and food industries) and the temperature is not high, ER308L or ER308LSi should be selected to obtain better resistance to intergranular corrosion; ER308LSi has better welding processability.