South American Welding Materials Market Growth Drivers: What’s Driving Demand Growth?

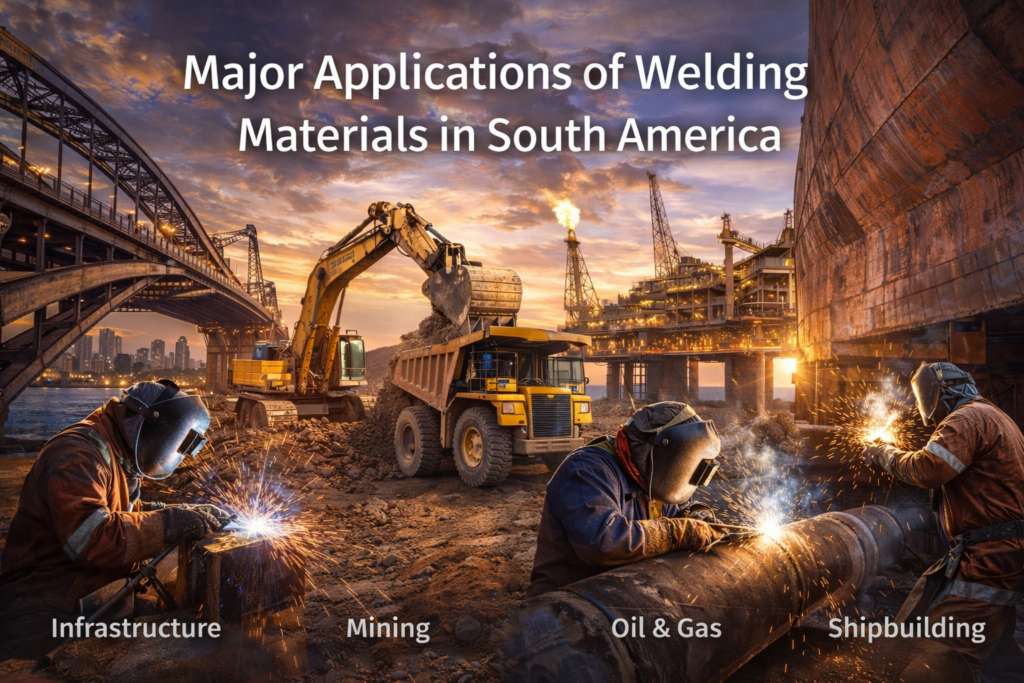

The South American welding materials market has experienced strong growth in recent years, driven by rapid expansion in several key industries. As industries increase investment in infrastructure, energy, mining, and shipbuilding, demand for welding consumables (including electrodes, wires, and fluxes) continues to rise.

This article will explore the drivers behind the growth in demand for welding materials in South America, and why industries such as mining, energy, construction, and shipbuilding are leading this growth wave.

🚧 1. Infrastructure Construction Activities

One of the main drivers of growth in the South American welding materials market is the continued expansion of infrastructure projects. Governments in countries such as Brazil, Argentina, Chile, Colombia, and Peru have invested in the following areas:

① Roads, bridges, and urban infrastructure

② Expansion and modernization of ports and airports

③ Construction of public housing and industrial parks

These projects heavily rely on the fabrication of structurally reliable steel structures, which in turn stimulates the consumption of welding materials such as solid welding wire and electrodes.

⛏️ 2. Mining Industry: Major User of Welding Consumables

Mining remains a pillar industry in many South American economies, particularly in Chile and Peru. Due to the continuous operation of heavy machinery and the need for manufacturing and maintaining mining equipment, the mining industry in this region is one of the major consumers of welding materials.

Key areas of welding applications in the mining industry include:

① Equipment repair and reinforcement

② Mining infrastructure construction

③ Pipeline and structural maintenance

Mining operations are often conducted in harsh environments, making reliable welding consumables crucial—especially those with good crack resistance and deposition rate.

⚡ 3. Energy Industry: Oil, Gas, and Renewable Energy

The South American energy industry, particularly offshore oil and gas projects in Brazil, is another significant demand driver. Welding applications in this industry include:

① Pipeline connections and maintenance

② Tank manufacturing

③ Refinery and petrochemical plant construction

These facilities require welding consumables capable of withstanding high stress, corrosion, and temperature variations, further driving the demand for advanced welding wires.

Furthermore, the development of renewable energy infrastructure, such as the manufacture of wind towers and solar panels, is gradually driving growth in welding materials in the region, especially with the increasing prevalence of sustainable development and green technologies.

🚢 4. Shipbuilding and Heavy Manufacturing

Shipbuilding and marine engineering activities are increasingly active in coastal countries such as Brazil. Welding materials, such as flux-cored wires and electrodes, are in high demand in the following areas:

① Hull construction

② Repair and refitting projects

③ Offshore structures

The requirement for corrosion resistance and fatigue-resistant weld durability makes it a key consumer area for welding materials.

🏭 5. Industrial Manufacturing and Production Growth

Although the South American welding materials market is smaller than major regions such as Asia Pacific or Europe, its growth momentum is strong. Infrastructure upgrades, industrial expansion, and booming automotive and manufacturing activities—particularly in Brazil and Mexico—support continued demand for welding consumables across a variety of applications.

🔧 New Trends Driving Long-Term Growth

Several emerging trends are also influencing the market:

👉 The Adoption of Semi-Automatic Welding Technology

While manual welding remains prevalent, semi-automatic welding technology is increasingly being adopted in manufacturing and large-scale industrial projects. This shift improves weld quality and consistency, leading to increased consumption of consumables.

👉 Sustainable and Environmentally Friendly Welding Consumables

Environmental concerns and rising workplace safety standards are driving the adoption of low-smoke electrodes and energy-efficient welding materials, aligning with global sustainability trends.

In summary, key drivers include:

① Infrastructure expansion and construction demand

② High consumption demand in the mining industry

③ Energy projects in the oil and gas and renewable energy sectors

④ Shipbuilding and marine engineering

⑤ Industrial manufacturing and production expansion

These industries continue to drive and grow demand for high-quality welding consumables, positioning South America as a key regional market for global welding materials.