Austenitic Stainless Steel Welding

I. Core Definition: What is Austenitic Stainless Steel?

Austenitic stainless steel welding refers to stainless steel with a predominantly austenite structure when in use. Simply put, its microstructure is a face-centered cubic crystal structure, achieved by adding high levels of austenite-forming elements such as nickel (Ni), manganese (Mn), and nitrogen (N) to an iron-chromium alloy. Austenitic Stainless Steel Welding

The most crucial point: Austenitic stainless steel is non-magnetic (it may become slightly magnetic after cold working) and cannot be strengthened by heat treatment (hardening by quenching), but only by cold working.Austenitic Stainless Steel Welding

II. How is it made? — The principles of “stainless steel” and “stainless steel”

● The cornerstone of “stainlessness”: Chromium (Cr). Chromium is the core element of all stainless steel. When the chromium content in steel exceeds 10.5%, an extremely thin and dense chromium oxide film (Cr₂O₃) forms on its surface. This “passivation film” prevents the iron within from further reacting with external oxygen and moisture, thereby providing corrosion resistance. Austenitic stainless steel typically contains at least 16% chromium.

● The key to the “austenitic” structure: nickel (Ni). Iron naturally exists in a different structure (ferrite) at room temperature. However, the addition of sufficient nickel (usually >8%) can preserve the high-temperature austenitic structure stably at room temperature, resulting in room-temperature austenitic stainless steel. This structure imparts the material with excellent toughness, ductility, and corrosion resistance.

Simple formula: High chromium (Cr) + high nickel (Ni) = austenitic stainless steel.

III. Main Characteristics (Advantages and Disadvantages)

Advantages:

● Excellent corrosion resistance: It offers excellent resistance to most organic and inorganic acids, salts, and alkaline solutions, making it the most widely used corrosion-resistant steel.

● Excellent comprehensive mechanical properties: It possesses high toughness and ductility, making it less susceptible to brittle fracture.

● Good weldability: Compared to other types of stainless steel, austenitic stainless steel offers the best weldability and generally requires no preheating or postheating.

● Non-magnetic: This is the most obvious difference between austenitic stainless steel and martensitic and ferritic stainless steels. (However, it may exhibit slight magnetism after cold working.)

● Good low-temperature performance: Does not become significantly brittle at low temperatures, making it suitable for cryogenic equipment and containers.

● Easy workability and formability: Easy to perform hot and cold processes such as rolling, drawing, and stamping.

Disadvantages:

● Low strength and hardness: Its strength and hardness at room temperature are the lowest among all stainless steels.

● Susceptible to intergranular corrosion:

?:Problem: In the 450-850°C temperature range (such as during welding), carbon (C) combines with chromium (Cr) to form chromium carbides, which precipitate at grain boundaries, resulting in chromium depletion near the grain boundaries and loss of corrosion resistance.

!:Solutions:

① Reduce carbon content: Use ultra-low carbon grades (such as 304L and 316L, with C ≤ 0.03%) to fundamentally reduce carbide formation.

② Add stabilizing elements: Add titanium (Ti) or niobium (Nb) (such as 321 and 347). These preferentially combine with carbon, preventing chromium consumption.

●Susceptibility to stress corrosion cracking (SCC): Brittle cracking is easily caused by the combined effects of tensile stress and a corrosive environment containing chloride ions.

●High cost: Because it contains a large amount of precious metal nickel, its price is relatively high and fluctuates greatly.

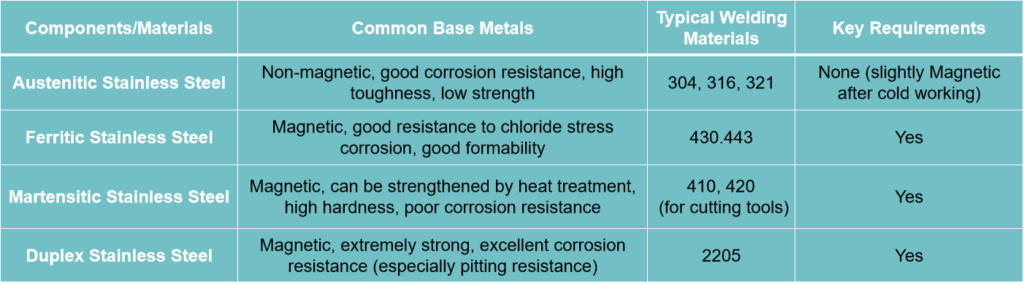

IV. A Brief Comparison with Other Stainless Steel Types

When selecting austenitic stainless steel welding consumables, the most important principle is to ensure that the chemical composition of the weld metal matches that of the base material and that its corrosion resistance and mechanical properties are at least as good as those of the base material. The weldment’s operating environment (e.g., temperature, medium) and service requirements (e.g., heat resistance and corrosion resistance) must also be considered.

I. Main Types of Welding Consumables

● Welding Rods: For manual arc welding.

● Solid Wire: For TIG (Tungsten Inert Gas) or MIG/MAG (Metal Inert/Active Gas) welding.

● Flux-Cored Wire: For MAG or self-shielded welding, offering high efficiency and suitable for outdoor operations.

● Flux: For use with submerged arc welding in conjunction with the welding wire.

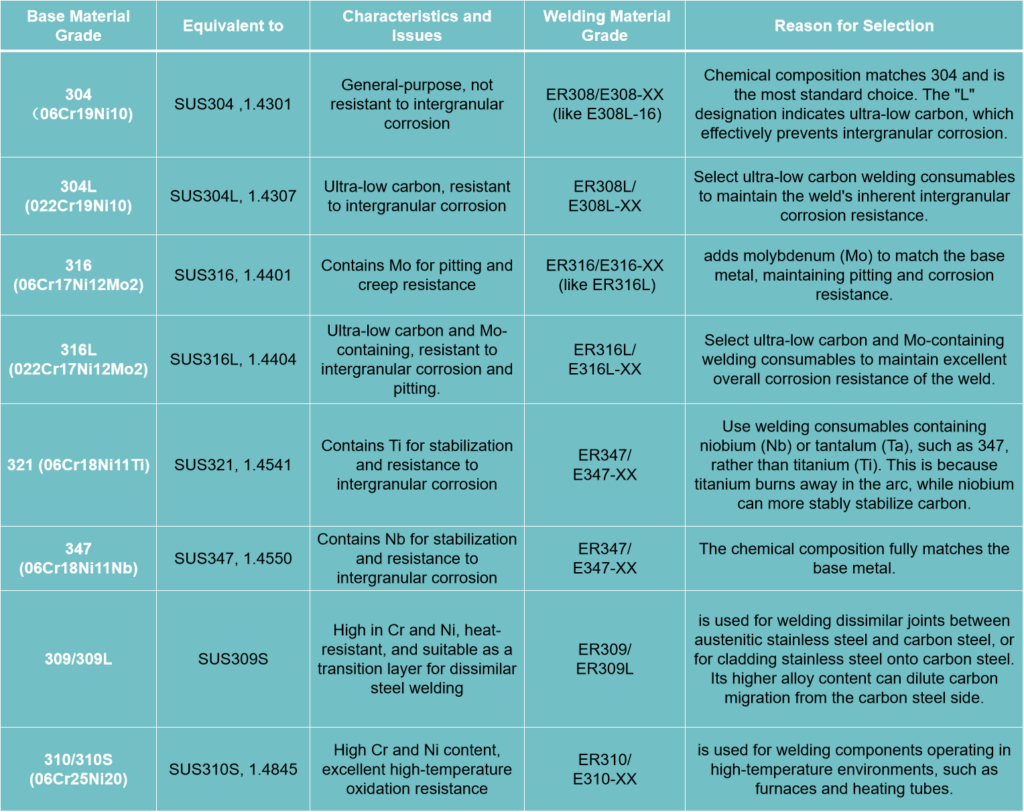

II. Common Austenitic Stainless Steel Base Materials and Compatible Welding Consumables

The following are some of the most commonly used austenitic stainless steels and their corresponding welding consumable grades under international standards (e.g., AWS A5.4/A5.9) and the Chinese National Standard (GB/T).

Notes:

●ER indicates welding wire (e.g., ER308L).

●E indicates welding rod (e.g., E308L-16).

●The -L suffix indicates ultra-low carbon (Carbon ≤ 0.03%), which is crucial for intergranular corrosion resistance.

●The -XX suffix indicates the coating type or welding position (e.g., -16 indicates rutile or calcium-titanium coating, suitable for all-position welding).

III. Key Considerations for Selecting Welding Materials

1. Operating Environment:

● Corrosive Environments: Welding materials with ultra-low carbon (L) or containing stabilizing elements (Nb) must be selected to prevent intergranular corrosion. For environments with pitting corrosion caused by chloride ions (such as seawater), welding materials with higher molybdenum (Mo) content (such as 316L series or even duplex steels) should be selected.

● High-Temperature Environments: Welding materials with higher alloying content and better high-temperature stability, such as the 310 series, should be selected.

2. Welding Dissimilar Steels:

● Austenitic Stainless Steel and Carbon Steel: 309/309L welding materials are typically used as transition layers. Because of their high chromium and nickel content, they can withstand carbon dilution from the carbon steel side, preventing the formation of a brittle martensitic layer.

● Between different austenitic stainless steels: Welding materials that match the higher alloy grade are typically selected. For example, when welding 304 and 316, 316 series welding materials are typically used.

3. Hot Cracking Susceptibility:

● Austenitic stainless steels are susceptible to hot cracking (solidification cracking) when welding. The formation of a small amount of ferrite in the weld metal (typically controlled to 3-12% FN) can significantly improve hot cracking resistance.

● Most standard welding rods/wires (such as 308 and 316) are designed with this in mind, and their chemical composition (chromium equivalent/nickel equivalent ratio) ensures the formation of an appropriate amount of ferrite.

● For fully austenitic welds or welds with strict ferrite content requirements (such as those used in ultra-low temperature environments), specially formulated welding consumables (such as high-manganese welding consumables) are required.

4. Welding Methods:

● TIG welding: The most commonly used method, offering excellent shielding and a clean weld, is suitable for thin plates and demanding applications. Use pure argon shielding.

● MIG/MAG welding: Highly efficient and suitable for medium and thick plates. The shielding gas is typically Ar + (1-2)% O₂ or Ar + (5-30)% CO₂. Note that excessive CO₂ content may increase the carbon content and affect corrosion resistance. Therefore, for demanding applications, an Ar+O₂ mixture is recommended.

● Stick arc welding: Flexible, suitable for all-position welding and outdoor operations, but with lower efficiency.

IV. Summary and Recommendations

●. Primary Matching: First, select the corresponding welding consumables based on the base metal type (304 → 308, 316 → 316, 321/347 → 347).

●. Confirm the carbon content: For welds requiring intergranular corrosion resistance, be sure to select ultra-low carbon welding consumables with an “L” designation.

●. Consider the operating conditions: Use 310 for high temperatures, 309 for dissimilar steels, and molybdenum-containing welding consumables for pitting resistance.

●. Process Coordination: Utilize low heat input, rapid welding, narrow-pass welding, and interpass cooling (≤150°C) to minimize the effects of welding heat and maintain the material’s corrosion resistance.