Diffused hydrogen

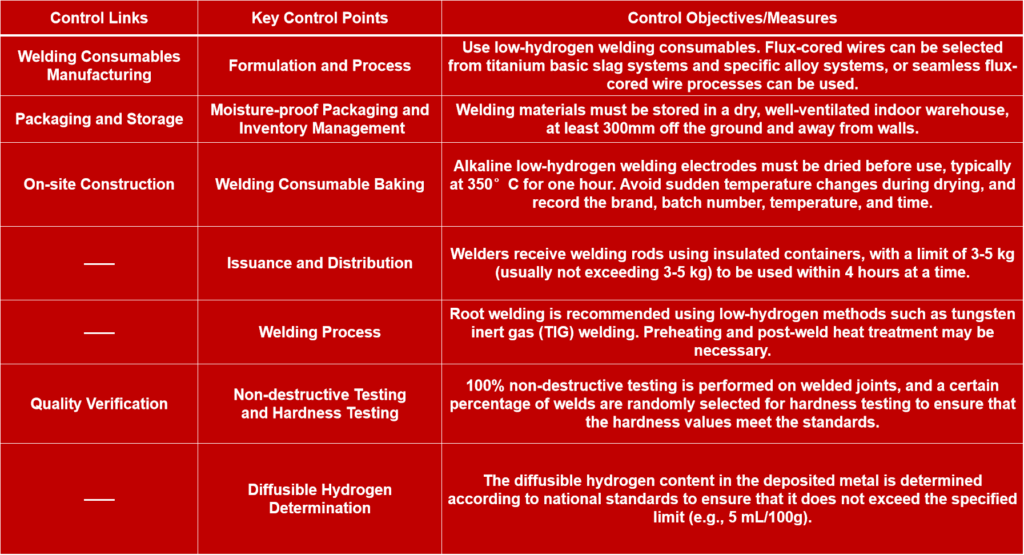

To ensure welds achieve ultra-low hydrogen levels (≤5mL/100g) or even extremely low hydrogen levels (≤2mL/100g), the key lies in establishing a comprehensive control system covering welding material manufacturing, packaging, storage, and on-site construction. This system effectively reduces the risk of hydrogen-induced cooling cracking and ensures the welding safety of high-strength steel structures.Diffused hydrogen

一:Diffused hydrogen,Key Control Points for Critical Stages

二:Diffused hydrogen,The Deep Logic of Building a Control System

Besides following the above process, understanding the underlying principles will help you better grasp the key points in practice:

❶ Diffused hydrogen,Sources and Core Control of Hydrogen:

Hydrogen in the weld mainly comes from moisture in the welding material coating/flux, moisture in the air, and oil contamination during the welding process. Therefore, the core of the entire system is “moisture prevention” and “hydrogen removal.” From the high-temperature baking and sealed packaging of the welding materials at the factory to the re-drying before use and the heat preservation during use, every step is aimed at cutting off the source of hydrogen.

❷ Diffused hydrogen,Achieving “Ultra-Low Hydrogen” and “Extremely Low Hydrogen”:

To achieve an extremely low hydrogen level of ≤2mL/100g, conventional measures are insufficient. This requires addressing the issue at its source, such as using seamless flux-cored wire technology in welding material manufacturing or using fluxes with exceptional moisture resistance. On-site, stricter moisture control is needed for dried welding materials, such as setting up constant-temperature insulation boxes next to high-temperature ovens, ensuring immediate use and minimizing contact time with air.

❸ Diffused hydrogen,The Ingenious Use of Process Synergy and Post-Heat Treatment:

The choice of welding method is crucial. TIG welding, due to the purity of its protective gas, effectively prevents the intrusion of moisture from the air. Furthermore, post-weld low-temperature heating is a key process; it is not traditional stress-relief annealing. Its core function is to accelerate the escape of diffusible hydrogen from the weld, reducing its content below the critical value for crack formation, thereby effectively preventing crack initiation.

三:Diffused hydrogen,Summary

Hopefully, this complete control system provides you with clear guidance. If you could share more information about your specific project (such as the grade of steel being welded, the type of product structure, etc.), I might be able to offer more targeted advice.