shipbuilding welding consumables: Materials and Requirements

Shipbuilding is one of the most demanding industries for welding. From hull construction to offshore structures, shipbuilding welding consumables play a critical role in ensuring structural integrity, safety, and long-term durability in harsh marine environments.

1. shipbuilding welding consumables:Common Base Materials in Shipbuilding

Ship structures are exposed to saltwater, cyclic loading, and low temperatures. Typical base materials include:

Carbon and Low-Alloy Shipbuilding Steels

Grades such as AH36, DH36, EH36

Used in hulls, decks, bulkheads, and frames

Require good toughness and crack resistance

High-Strength Structural Steels

Used to reduce weight and increase payload capacity

Require controlled hydrogen levels and excellent impact toughness

Stainless Steels

Applied in tanks, piping, and corrosion-sensitive areas

Require corrosion-resistant weld metal and proper heat input control

Aluminum Alloys

Used in superstructures and high-speed vessels

Require lightweight consumables with excellent crack resistance

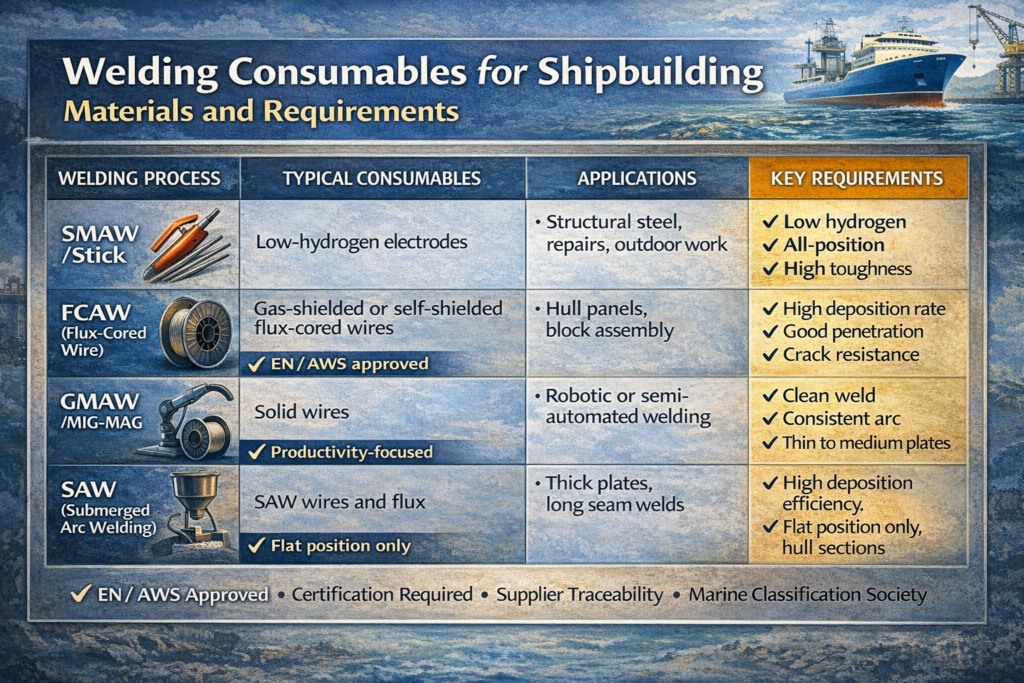

2. shipbuilding welding consumables:Key Welding Consumables Used in Shipbuilding

Shipyards use a wide range of consumables depending on joint design and productivity needs.

Shielded Metal Arc Welding (SMAW) Electrodes

Low-hydrogen electrodes for structural welding

Good arc stability and all-position capability

Commonly used for repairs and outdoor welding

Flux-Cored Wires (FCAW)

High deposition rate and good penetration

Widely used in panel lines and block assembly

Available in gas-shielded and self-shielded types

Solid Wires (GMAW / MIG-MAG)

Used in automated and robotic welding systems

Clean weld appearance and high productivity

Suitable for thin to medium plate thickness

Submerged Arc Welding (SAW) Consumables

Ideal for long, straight welds and thick plates

High deposition rate and excellent weld quality

Commonly used in flat-position welding of hull sections

3. shipbuilding welding consumables:Technical Requirements for Shipbuilding Welding Consumables

Classification Society Approval

Welding consumables must be approved by major classification societies, such as:

ABS

DNV

LR

BV

CCS

Approval ensures compliance with marine safety standards.

Mechanical Properties

Consumables must meet strict requirements for:

Tensile strength

Yield strength

Impact toughness at low temperatures

Hydrogen Control

Low diffusible hydrogen levels are essential to:

Prevent hydrogen-induced cracking

Ensure long-term weld reliability in thick plates

Weldability and Productivity

Consumables should provide:

Stable arc performance

Low spatter and easy slag removal

High deposition efficiency for shipyard productivity

4. shipbuilding welding consumables:Environmental and Service Conditions

Marine welding consumables must withstand:

Corrosion from seawater and humidity

Dynamic and fatigue loading

Temperature variations in different sea zones

Proper consumable selection contributes to extended service life and reduced maintenance costs.

5. shipbuilding welding consumables:Quality Control and Certification

Reliable suppliers provide:

Mill Test Certificates (MTC)

Batch traceability

Compliance with ISO 9001 quality systems

Consistent performance across production batches

These factors are critical for shipyards operating under strict inspection regimes.

Conclusion

Selecting the right welding consumables is essential for shipbuilding success. From material compatibility and classification approvals to productivity and hydrogen control, every detail matters.

By choosing certified, high-quality welding consumables, shipyards can ensure structural safety, operational efficiency, and long-term performance in one of the world’s most challenging environments.