What Are Welding Consumables?

Types, Functions and Applications

Welding consumables are essential materials used during the welding process to create and protect the weld joint. They directly affect weld quality, mechanical performance, productivity, and long-term reliability across industries such as construction, automotive manufacturing, energy, shipbuilding, and mining.

Understanding what welding consumables are, how they work, and where they are applied is critical for engineers, procurement managers, and distributors seeking consistent and compliant welding results.

Stay updated on LinkedIn news:【https://www.linkedin.com/in/gan-%EF%BC%88arcfort%EF%BC%89-5092a2242/】

Welding consumable are materials that are consumed during the welding process to form the weld metal, protect the molten weld pool, or stabilize the arc. Unlike welding equipment, consumables must be replenished continuously and are selected based on:

Base material type

Welding process

Mechanical property requirements

Applicable standards (AWS, EN ISO)

Main Types of Welding Consumables

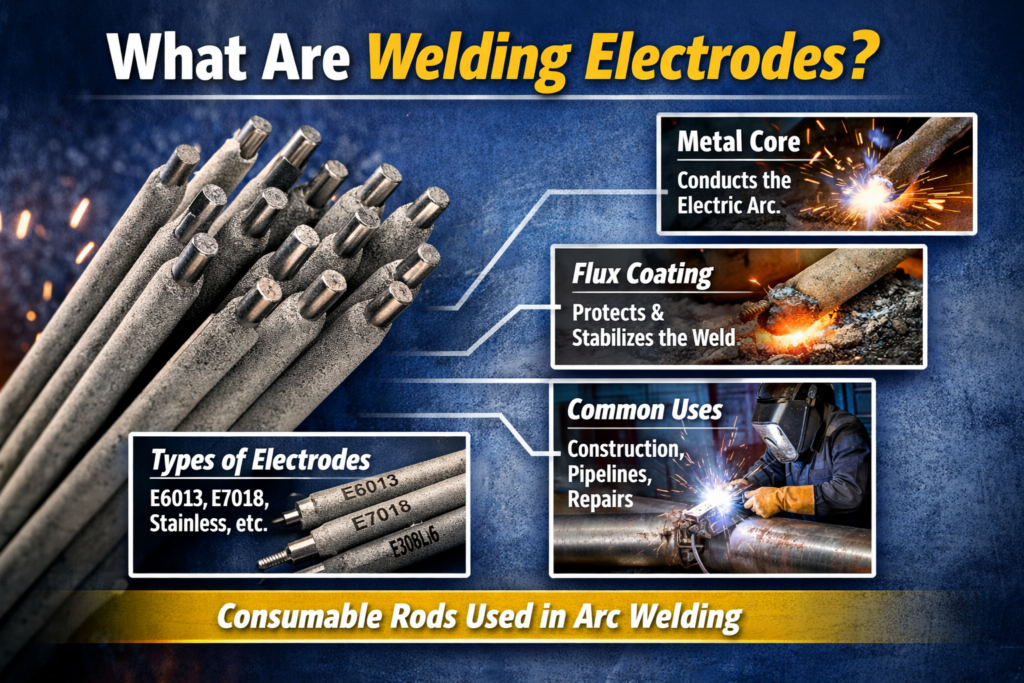

1. Welding Electrodes

Welding electrodes are among the most widely used welding consumable, especially in SMAW (Stick Welding).

Covered electrodes (e.g. E6013, E7018, E308L)

Provide arc stability and slag protection

Suitable for construction, maintenance, and field welding

2. Welding Wires

Welding wires are used in GMAW (MIG) and GTAW (TIG) welding processes.

Solid wires (ER70S-6, ER308L)

Flux-cored wires (FCAW)

High deposition efficiency and consistent quality

3. Flux-Cored Welding Consumables

Flux-cored wires combine the advantages of electrodes and solid wires.

Self-shielded or gas-shielded

Higher productivity than solid wire

Widely used in heavy fabrication and shipbuilding

4. Welding Fluxes

Welding fluxes are primarily used in Submerged Arc Welding (SAW).

Protect the molten weld pool

Improve bead appearance and mechanical properties

Common in pressure vessels, pipelines, and large steel structures

Functions of Welding Consumables

Welding consumable serve multiple critical functions:

Forming the Weld Metal

Forming the Weld Metal

They provide the filler material that bonds base metals together.

Protecting the Weld Pool

Protecting the Weld Pool

Flux coatings and shielding gases prevent contamination from oxygen and nitrogen.

Controlling Mechanical Properties

Controlling Mechanical Properties

Consumables determine tensile strength, impact toughness, and crack resistance.

Improving Productivity

Improving Productivity

Proper consumable selection reduces rework, spatter, and downtime.

Applications of Welding Consumables by Industry

Construction & Infrastructure

Structural steel fabrication

Bridges, buildings, railways

Common products: E6013, E7018 electrodes

Automotive Manufacturing

Thin sheet welding

Robotic MIG/TIG welding

Common products: solid wires, metal-cored wires

Energy & Oil & Gas

Pipelines, pressure vessels

Low hydrogen and high toughness consumables required

Shipbuilding & Offshore

Thick plate welding

Flux-cored wires and SAW consumables widely used

Mining & Heavy Equipment

Wear-resistant and repair welding

High-strength electrodes and wires

Welding Consumables vs Welding Equipment

A common misconception is confusing welding consumable with welding machines.

| Welding Consumable | Welding Equipment |

|---|---|

| Used up during welding | Reusable machines |

| Electrodes, wires, fluxes | Welding machines, torches |

| Affect weld quality directly | Provide power and control |

How to Choose the Right Welding Consumables

Key selection factors include:

Base material composition

Welding position and environment

Required mechanical properties

Applicable standards (AWS / EN ISO)

Storage and handling conditions

Choosing the correct consumables improves weld integrity and reduces total welding cost.

Conclusion

Welding consumable play a decisive role in weld quality, productivity, and compliance. From electrodes and wires to fluxes and flux-cored products, understanding their types, functions, and applications allows manufacturers and distributors to make informed decisions and achieve consistent welding performance across industries.

For detailed product selection or technical support, exploring application-specific welding consumable is the next step.

Back【ARCFORT UNIVERSITY- Welding】 https://www.akweld.com/elementor-6581/