welding electrode storage and selection

In several manufacturing projects across South America, we often see companies focus heavily on welding machines and operators, but underestimate how welding electrode selection and storage affect weld quality.welding electrode storage and selection

In countries like Brazil and Chile, high humidity and temperature changes can significantly increase the risk of moisture absorption in electrodes, leading to defects, rework, and lower productivity.

In a few cases, defect rates were reduced simply by using more suitable electrode types and improving storage and handling practices — without changing equipment or processes.

Small adjustments in welding consumables often make a bigger difference than expected.

How do you usually manage welding electrode storage and selection in high-humidity environments?

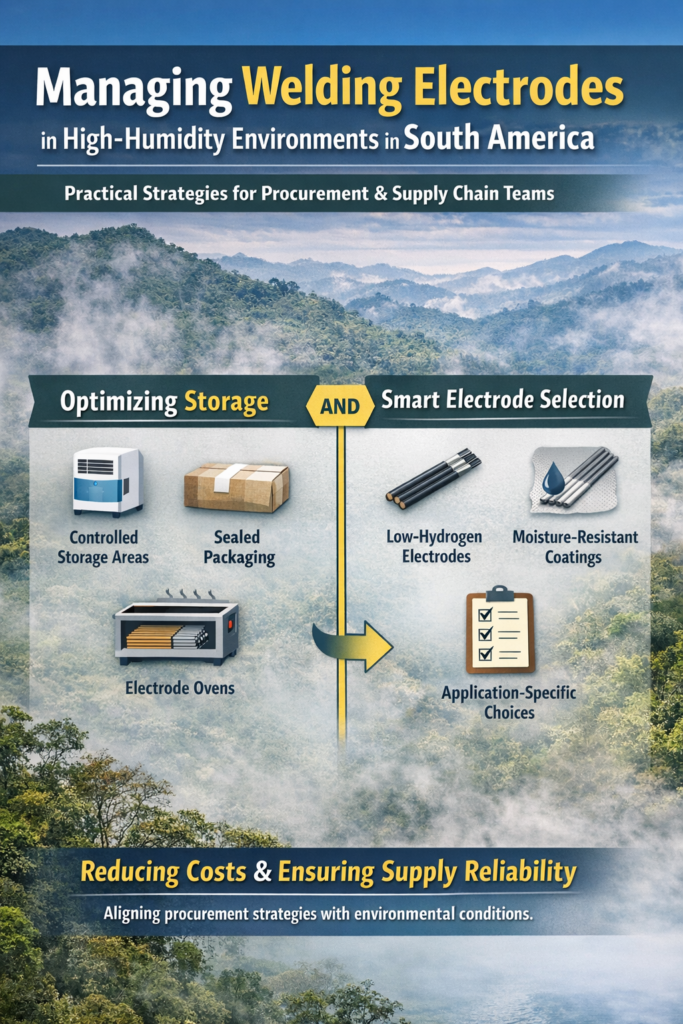

In many South American countries, high humidity is a constant challenge for manufacturing operations. For procurement and supply chain teams, welding electrodes are often treated as standard consumables. However, in humid environments, poor storage and unsuitable electrode selection can quickly translate into higher costs, rework, and unstable production.

From a procurement perspective, effective electrode management usually focuses on risk control, supply reliability, and total cost, rather than unit price alone.

1. welding electrode storage and selection:Storage Management as a Cost-Control Tool

In high-humidity regions such as Brazil and Colombia, moisture-related welding defects can significantly increase rework rates. To reduce this risk, many procurement teams work closely with production to ensure:

- Electrodes are stored in controlled environments with basic humidity management

- Packaging remains sealed until actual use

- Low-hydrogen electrodes are supported with proper holding ovens

- Clear rules are in place for exposure time and material handling

These measures help protect material value and reduce hidden costs caused by scrap and downtime.

2. welding electrode storage and selection:Electrode Selection Beyond Price Comparison

Procurement decisions in humid environments often require a broader evaluation:

- Low-hydrogen electrodes are commonly selected for critical structures to reduce defect risks

- Moisture-resistant coatings help improve consistency during handling

- Stable quality and supply reliability are often prioritized over short-term price advantages

In many cases, choosing a more suitable electrode reduces overall production costs, even if the initial unit price is slightly higher.

3. Procurement Impact on Production Stability

Many manufacturers report that improving electrode selection criteria and storage coordination can stabilize welding quality without changing equipment or increasing labor. From a procurement standpoint, this approach supports long-term production planning and reduces unexpected quality-related costs.

Conclusion

For procurement teams in South America, managing welding electrodes in high-humidity environments is not just a technical issue—it is a strategic cost and risk management decision. Aligning material selection with environmental conditions can significantly improve production stability and total cost performance.