Which Welding Materials Are Used in Oil and Gas Pipelines?

“In the oil and gas industry, a single weld can mean the difference between safe, reliable operations and costly failures—choosing the right materials is not optional, it’s mission-critical.” Welding Materials in Oil and Gas Pipelines

1. Welding Materials in Oil and Gas Pipelines:Introduction: Why Welding Materials Matter in Pipelines

Oil and gas pipelines operate under extreme conditions—high pressures, fluctuating temperatures, corrosive environments, and sometimes remote locations. Selecting the proper welding materials ensures:

Structural integrity

Leak prevention

Corrosion resistance

Compliance with international codes and standards

A wrong choice could compromise pipeline safety and lead to catastrophic consequences.

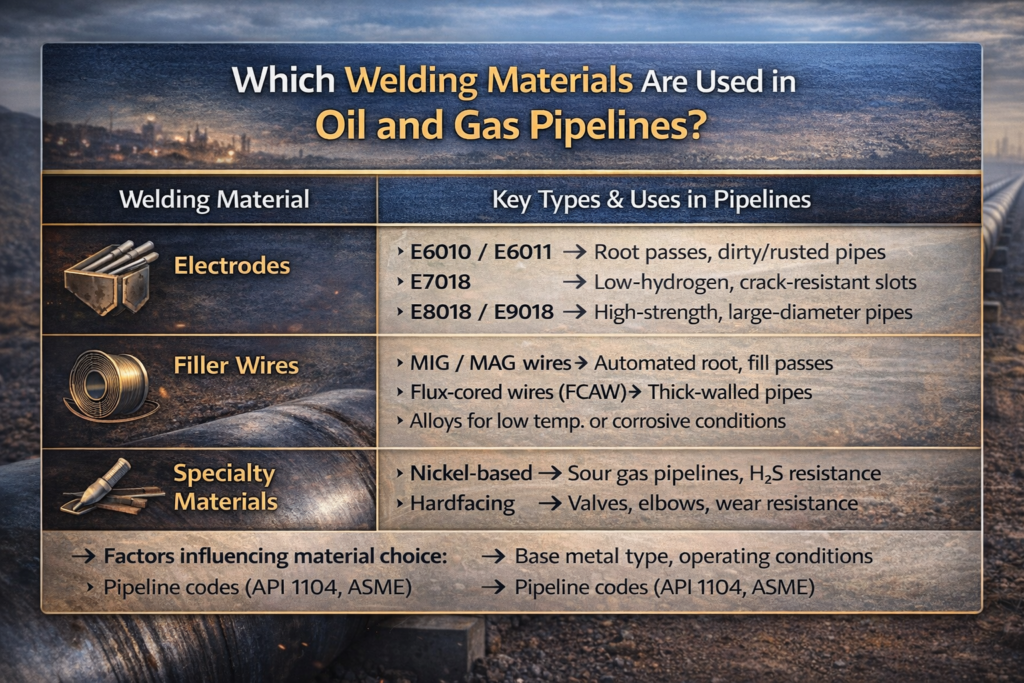

2. Welding Materials in Oil and Gas Pipelines:Common Welding Materials for Pipelines

a) Electrodes

E6010 / E6011: Deep penetration for root passes, ideal for dirty or rusted pipes

E7018: Low-hydrogen electrode for high-strength, crack-resistant welds

E8018 / E9018: Special high-strength applications, especially for large-diameter pipelines

b) Filler Wires

MIG / MAG wires: Often used in automated pipeline welding

Flux-cored wires (FCAW): High deposition rates, suitable for thick pipes

Alloy-specific wires for low-temperature or high-corrosion pipelines

c) Specialty Materials

Nickel-based electrodes: For corrosion-resistant pipelines transporting sour gas (H₂S)

Hardfacing rods: Applied on valves or elbows to resist erosion and wear

3. Welding Materials in Oil and Gas Pipelines:Factors Influencing Material Selection

Base Metal Type – Carbon steel, stainless steel, or nickel alloys

Operating Conditions – Pressure, temperature, and corrosive environments

Pipeline Codes & Standards – ASME, API 1104, ISO 3183

Welding Position & Accessibility – Field welds vs. shop fabrication

Cost and Availability – Balancing performance and supply chain reliability

4. Welding Materials in Oil and Gas Pipelines:Best Practices for Pipeline Welding

Maintain low-hydrogen conditions to prevent cracking

Preheat and post-weld heat treatment (PWHT) as required

Conduct non-destructive testing (NDT) on critical joints

Keep electrodes and wires dry with proper storage

5. Conclusion: Welding Materials Are Pipeline Lifelines

Choosing the right welding materials is not just a technical detail—it’s the backbone of pipeline safety, efficiency, and longevity. Oil and gas companies, EPC contractors, and welding service providers must invest in quality, traceability, and expertise to avoid costly failures.