Basic Concept

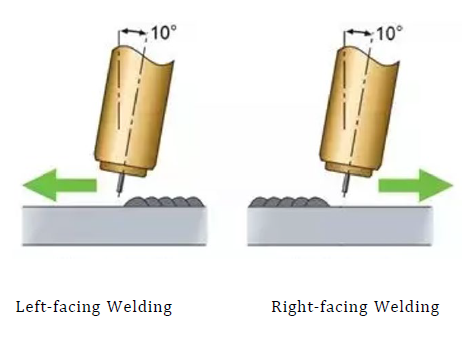

Melting pole gas shielded welding, the operator holds the torch in the right hand, from right to left direction welding, torch nozzle and welding direction is obtuse angle (> 90 °) is called the left welding method; from left to right direction welding, torch nozzle and the welding direction is an acute angle (< 90 °) is called the right welding method. If the operator’s left hand when holding the torch, the welding direction is just the opposite, Figure 1 for the left welding method and the right welding method schematic diagram.

Fig. 1 Schematic diagram of the leftward and rightward welding methods

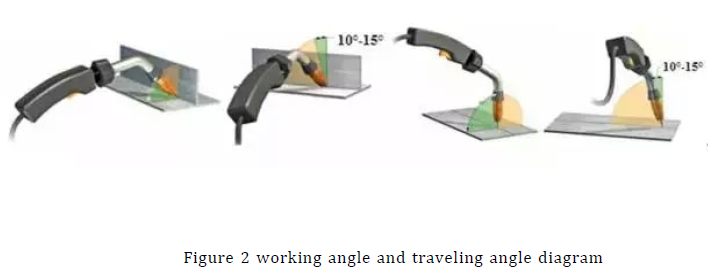

The angle between the torch axis and the surface of the weldment is the working angle;

In the plane where the torch axis and the welding direction are located, the angle between the torch axis and the straight line perpendicular to the welding direction is the traveling angle.

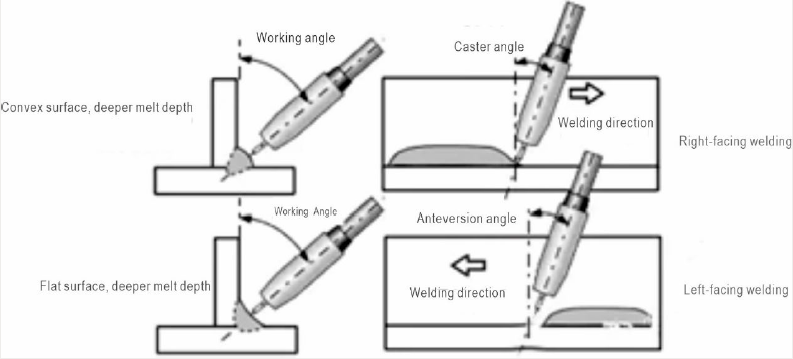

Figure 2(a) shows the working angle and traveling angle of fillet weld, and Figure 2(b) shows the working angle and traveling angle of butt weld. Normally, the angle of fillet weld is 45 °, the angle of butt weld is 90 °; which walking angle according to the different welding directions, and there are front angle and back angle of difference, the right welding is called back angle, the left welding is called front angle.

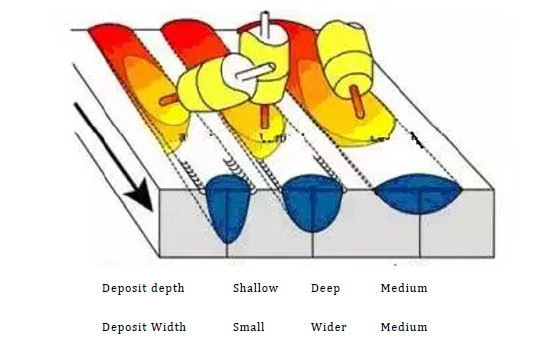

The impact on weld shaping welding direction and angle is different, the arc and the weldment play a different role, the right welding arc most of the direct role in the weldment, while the left welding arc most of the role in the liquid molten pool, so in the same welding current, arc voltage, welding speed conditions, the weld width and depth of fusion will be different, Figure 3 for the direction and angle of the welding and its impact on weld shaping schematic diagram.

(a) chematic diagram of the influence of weld direction and travel angle on weld shaping for butt welds

(b) Schematic diagram of the influence of welding direction and travel angle on weld shaping of fillet weld

3 Schematic diagram of the influence of welding direction and angle of travel on weld shaping

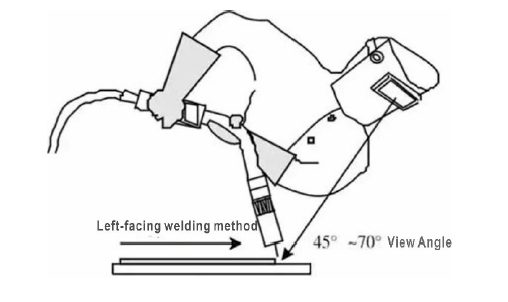

In addition to the impact on the weld formation, welding direction and walking angle of the welder’s molten pool observation, the size of the spatter and gas protection effect also has a certain impact. Left welding, the operator’s line of sight from the welding arc side of the welding arc was 45 ° ~ 70 ° angle of view to observe the welding arc and welding pool, this angle is easy to observe the melting of the wire out of the end of the melting situation and the molten pool changes; right welding, the welding torch blocks the operator’s line of sight, the operation of the difficult. Figure 4 shows a schematic diagram of the operator’s view angle for leftward welding (flat welding position).

Fig. 4 Operator’s view of leftward

welding (flat welding

position)

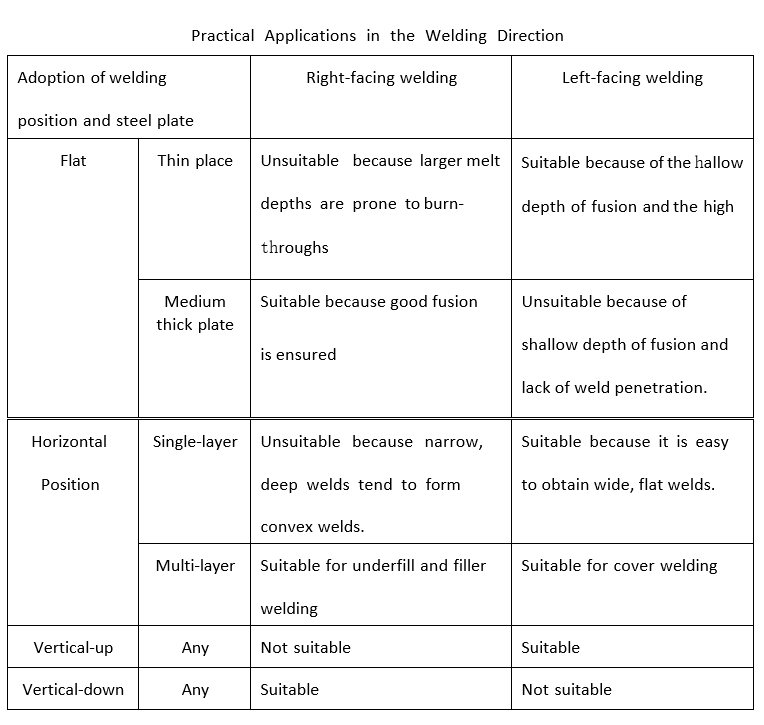

Welding direction and angle of application due to the welding direction and angle of the weld formation, spatter size, gas shielding effect has an important impact, so in the actual welding production, according to different technical requirements and the actual situation, the left welding and right welding will have different occasions, the typical welding direction of the application of the practice of the attached table.

Conclusion

The left welding method is characterized by shallow melt depth and wide weld channel, suitable for thin plate welding; the right welding method is characterized by large melt depth and narrow weld channel, suitable for medium-thick plate welding. When the travel angle is small, it has the characteristics of large melt depth and good melt pool protection; when the travel angle is large, it has the characteristics of small melt depth and poor melt pool protection; when the travel angle is 10°~15°, the melt pool protection is good.